Wool is a fiber made by spinning the fur of hairy mammals, usually sheep, into yarn. The yarn is then woven or knitted into a fabric. Wool fabric is used used to make socks, gloves, sweaters, and other garments for cold weather.

Wool fabric is an ancient material that likely originated in ancient Iran. Estimates date the first use of wool in clothing to as early as 4000 BCE. While most modern wool is made from sheep, it has also been made from camels and goats.

Wool is good at taking up dyes, which means it comes in various vibrant and deep colors. It is low-density, so it often makes a lightweight but warm fabric. These unique characteristics are why wool has remained popular for thousands of years.

Since the early 20th century, wool has been decreasing in popularity. In Australia, for example, wool production has dropped by 63% since 1990, according to GRO Intelligence, because many synthetic or plant-based alternatives to wool are easier to care for and less expensive to make.

Today, the world’s largest wool producers are China and Australia. Wool is used worldwide but is most popular in the United States, the United Kingdom, and Japan.

What Is Wool Fabric?

Wool fabric is a woven fabric made from wool yarn. Wool yarn is spun from the fur of mammals like sheep, alpacas, camels, goats, and llamas. Wool is also called fleece, fur, hair, tweed, and Cashmere. Wool is moderately breathable, highly absorbent, and warm in cold weather.

The most common uses for wool are suits, socks, and cold-weather gear like hats, gloves, and sweaters. Manufacturers also use wool to make carpets and insulation.

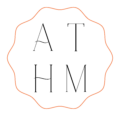

History of Wool Fabric

The history of wool fabric goes back about 1,000 years after the domestication of sheep. Before their domestication, sheep were primarily hairy animals, similar to most other mammals. Early sheep hair could not be used for textiles, though early humans used sheep skins for clothing and warmth across Europe and Asia.

As farmers bred sheep to have thicker and thicker coats, sheep gradually became fluffier and eventually began to grow the thick woolen coats that they’re known for today. Around 4000 BCE, humans learned how to spin this woolen material to make yarn and weave the yarn to make fabric, and wool fabric was born.

Wool Fabric in European History

Wool became important internationally around the 13th century. It was an essential export for the English, Irish, Italians, and many other European countries. Over the next few centuries, many countries would grow their wealth by selling either raw wool or finished wool products.

The Medici family made much of their large fortune by participating in the wool trade. However, they were so dependent on English wool that when supplies started to dwindle, they had to close several bank branches.

Wool Fabric in Australian History

The first sheep arrived in Australia in 1788. The first sheep came from South Africa and were not suited to Australia’s climate. As a result, most early Australian sheep did very poorly and produced low-quality wool.

Still, Australia managed to become one of the world’s largest wool producers, primarily due to the arrival of a particular Spanish sheep in 1797: The Merino.

Merino sheep adapted remarkably well to the Australian environment. The wool they produced was of the highest quality, and by the late 19th century, Merino wool was Australia’s largest export.

Properties and Characteristics of Wool Fabric

The properties and characteristics of wool fabric have made it a staple fabric for thousands of years because of its ability to hold color, warmth, and flexibility. Wool is also breathable, and though it is primarily known as a cold-weather fabric, it is also well suited for warmer temperatures.

Wool is remarkably easy to dye. Unlike most materials, wool takes both acidic and basic dyes.

The different colors of wool yarn can be woven together to create beautiful, rich, unique fabrics, making it popular in cultures worldwide for centuries.

Wool fabric is what textile experts call a “temperature regulator,” which keeps the wearer cool in the summer and warm in the winter. Wool absorbs water vapor, creating a natural barrier between the wearer and the environment.

In addition to its vibrancy and breathability, wool fabric is naturally elastic. On a microscopic level, wool is “spring-shaped,’ meaning that it returns to its original form even after being bent. This spring structure makes it comfortable, wrinkle-resistant, and easy to maintain.

Characteristics of Wool Fabric:

- Very breathable

- Moisture-wicking

- Temperature regulating

- Naturally elastic

- Pills easily

Types of Wool Fabric

There are many different kinds of wool fabric, depending on the animal it came from or the breed of sheep. The most common types of wool are Alpaca, Angora, Merino, Cashmere, Mohair, and Lambswool. Each type of wool has its benefits and drawbacks that make it suitable for different purposes.

Alpaca Wool

Alpaca fiber is warmer than most sheep wool and is lighter, stronger, and more resilient. Most Alpaca wool is made in South America. It is less used than sheep’s wool fabric because of its price and difficulty to procure.

Angora Wool

Angora wool comes from Angora rabbits. It is soft and fluffier than other wools and best at retaining heat and wicking away moisture. By itself, Angora is fragile, so it is often blended with other types of wool to make it stronger. As a result, angora wool fabric is one of the most expensive wools available.

Merino Wool

Merino is an Australian sheep’s wool, one of the world’s most common types. Merino is often used over other types of sheep wool because it is more resilient, easier to care for, and less expensive than other wools.

Cashmere

Cashmere is the softest wool fabric available. It is lighter than most wools but is still very good at keeping the wearer warm. Cashmere comes from cashmere goats that live in the Middle East and Asia. Despite being a woolen fabric, Cashmere is silky smooth to the touch. It is usually more expensive than other wools.

Mohair Wool

Mohair wool comes from Angora goats (which do not make angora wool, despite the name). Like most wools, Mohair is lightweight but good at insulating.

Mohair is more lustrous than other wools, so clothing made from it has a characteristic shine that sets it apart from other wool clothes. However, because of the complex process required to refine Mohair, it is one of the more expensive wools.

Lambswool

Lambswool is also often called virgin wool. Virgin wool is taken from a lamb at its first shearing, so a sheep can only produce lambswool once. Lambswool fabric is soft and less itchy than other kinds of wool, which makes it a popular choice for sweaters, scarves, and other clothing.

Camel Wool

Camel hair can be used to make luxurious wools. Usually, the camel hair is combined with other types of wool to make it less expensive. The undercoat of the camel is used to make wool for coats and apparel, while the outer coat is used for more industrial purposes.

Shahtoosh

Shahtoosh means the ‘king of wools’ in Persian. It is one of the finest wools available- but it is illegal to make, own, or sell. Shahtoosh comes from the endangered Tibetan Antelope. Historically, people collected the fur as it naturally shed, but as the fabric became popular, people began to kill the antelope for their skins.

Vicuna

The most expensive wool legally available is Vicuna. Vicunas are a wild endangered species that live in Peru. Because of their endangered status, Vicunas may only be sheared once every two years and only five times throughout their life. Vicuna wool is one of the most delicate fabrics in the world and can cost up to $3000 per yard.

Qiviut

Quivut wool comes from the Arctic musk ox. In the spring, the ox sheds its soft undercoat making the perfect fur for wool. It is more delicate and warmer than most other wools and doesn’t shrink in water.

Yak Wool

Yak wool has a looser fit than other wools, which allows the fabric to feel cooler. Yak wool has better airflow and is stretchier than most other wools.

Shetland Wool

Shetland wool comes from Shetland sheep, which are native to the Scotland Shetlands. The yarn is soft and fine—perfect for making knit sweaters that are warm enough for Scottish winters.

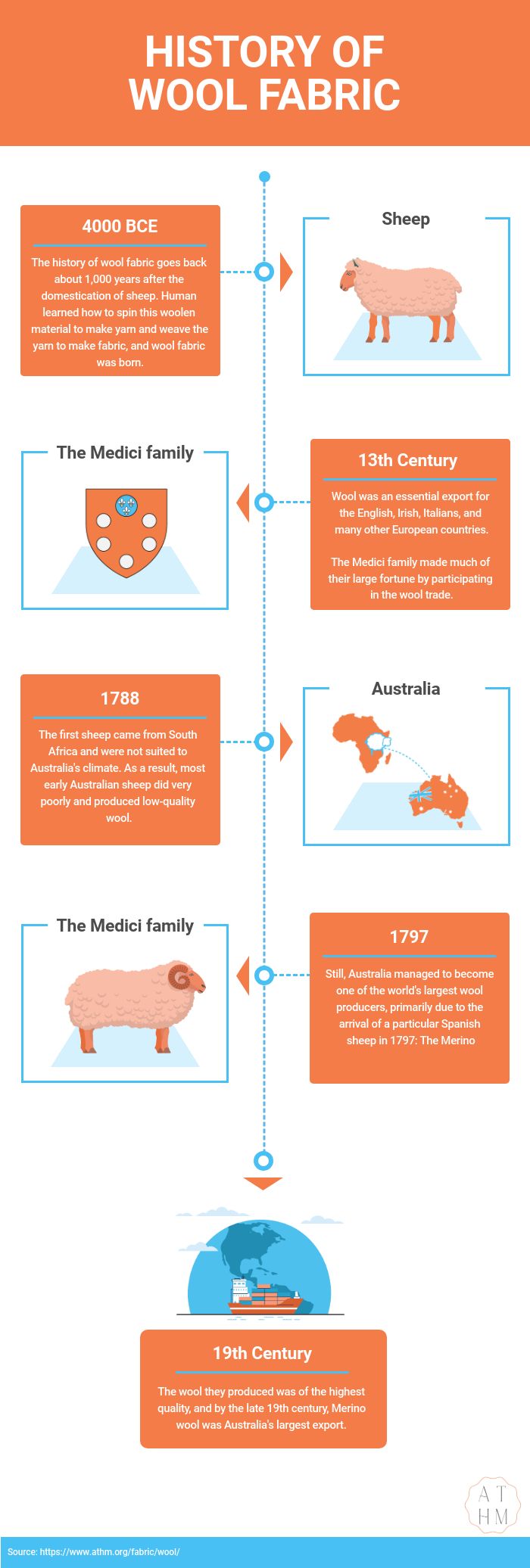

How Is Wool Fabric Made?

While the steps to making wool have remained largely the same for thousands of years, advancements in tools have made the creation of wool fabrics much easier and faster, allowing for the mass production of wool products.

Regardless of the tools used, there are seven steps to creating wool fabric:

1. Shearing

In most cases, fleece is taken from living animals. Historically, sheep’s fleece was plucked by hand or carefully combed out. In the iron age, shears became popular for quicker cutting. Today, most farmers use electric shears or shearing machines to remove the animal’s fleece quickly.

2. Souring

The wool has to be cleaned after it is removed from the animal. Most wool contains grease and oil from the animal’s skin and must be removed before further processing. Before soaps and lye were commonly available, stale human urine was the most common way of scouring wool.

Many, though not all, wools are dyed after the scouring process, before the sorting process.

3. Sorting

Different parts of an animal will produce different kinds of wool, so after the wool has been washed and dried, it is sorted by type and quality. In sheep, the best wool is taken from the shoulders and back, while the worst is taken from the legs.

4. Carding

Once the maker has separated the wool by quality, it is combed or carded, so the fibers face the same way. Carding the wool makes it easier to spin into yarn in the next process step.

Before the invention of the carding machine in 1748, wool had to be carded by hand with small combs. The carding machine, a hand-cranked spinning drum with a wire frame, made hand-carding nearly obsolete.

5. Spinning

A spinner or machine spins the carded wool into yarn. Spinning is most commonly done by twisting and pulling the material using a drop spindle or spinning wheel. Yarn can be made with different characteristics at this stage, depending on what the weaver wants- thick or thin, piled or un-piled.

If the wool is not dyed after the scouring stage, it is usually dyed after being spun into yarn skeins.

6. Weaving

The wool is then woven into a fabric. Weaving is usually done on a loom, but fabric made from wool yarn may also be knitted, felted, or crocheted.

7. Finishing up

Many types of wool are finished and ready for use after being woven, but some manufacturers use post-production methods to set their wool fabrics apart. For example, manufacturers may soak the wool to lock the fibers in place.

How Is Wool Fabric Used?

Because of its unique properties- fire resistance, moisture wicking, insulating- wool is used in many different ways. Uses for wool can be split into two main categories: industry and apparel.

Industrial Applications of Wool Fabric

Wool is often used in firefighting uniforms because it is fire-resistant. When it comes in contact with a flame, wool can put itself out quickly without melting or sticking to the skin. Wool is also used in insulation for the same reason and because it is a perfect temperature regulator.

Wool can also be found in cardboard, fertilizer, and carpets.

Apparel Uses for Wool Fabric

Wool fabric is most commonly used in garments. Softer varieties of wool are often used to make clothing that touches the skin, like sweaters, but most wool is used for outer garments like coats and hats because it is usually coarse and itchy.

Advantages of Wool Fabric

Wool holds moisture without feeling wet. It is warm, lightweight, and sustainable. Wool can be soft, though most soft varieties are more expensive.

Though it may seem odd, many manufacturers have begun using wool to make athletic wear. The varieties of wool used are usually soft, easy to care for, naturally elastic, and breathable. Additionally, wool fabrics naturally resist odors and bacteria, making them a perfect material for workout gear.

Wool is also often used in blankets because it meets fire safety standards without chemical treatments.

Disadvantages of Wool Fabric

While some varieties of wool are soft to the touch, such as Cashmere or lambswool, most wool is itchy and coarse. Unless adequately cared for, many types of wool pill easily, making them difficult to use in more casual apparel.

Although some manufacturers produce machine-washable, athletic-safe wool clothing, most wool is notoriously tricky to manage. Cashmere, for example, must be washed carefully in cold water. Agitating the fabric while it is wet, especially if wet and warm, will ruin it beyond repair.

Alternatives to Wool Fabric

There are many alternatives to wool fabric that are easier to care for and do not require the keeping of animals to produce, such as cotton, Tencel, hemp, and bamboo. Additionally, silk and linen are good alternatives that do not pill as quickly as wool.

Cotton vs. Wool

Cotton is far less expensive than wool and does not require the keeping of livestock. While wool produces more greenhouse gas emissions, cotton requires far more water. They are both biodegradable, non-synthetic materials, making them both environmentally-friendly choices.

Tencel vs. Wool

Tencel fabric is a type of rayon. It is a plant-based, semi-synthetic fiber, so it is a good alternative for vegans looking for a wool alternative. It is much easier to care for than most wool products because it can be washed and tumble-dried without worry.

While tencel modal is pill-resistant, pure tencel has a reputation for pilling easily.

Hemp vs. Wool

Hemp is another good vegan alternative to wool. Hemp also requires much less water to produce- while making wool fabric can take 170 thousand Liters of water per kilogram, hemp fabrics only take 2,700 liters. Hemp has also been shown to be more pill resistant than cotton and wool.

Bamboo vs. Wool

Bamboo fabric is pill and tear-resistant, so it is much easier to care for than wool. Bamboo fabric has the same anti-smell properties as wool without the itchy feeling of some wool fabrics. In addition, bamboo is sustainable and requires less water than cotton.

Silk vs. Wool

Silk is made from long strands of thread, which makes it much less likely to pill. However, silk is difficult to care for and is more expensive than wool.

Linen vs. Wool

Linen is less likely to pill than wool and easier to care for and makes an excellent vegan alternative to wool. Most linen fabrics are less expensive than wool as well. Linen does not require any livestock to make and is relatively fire-resistant.

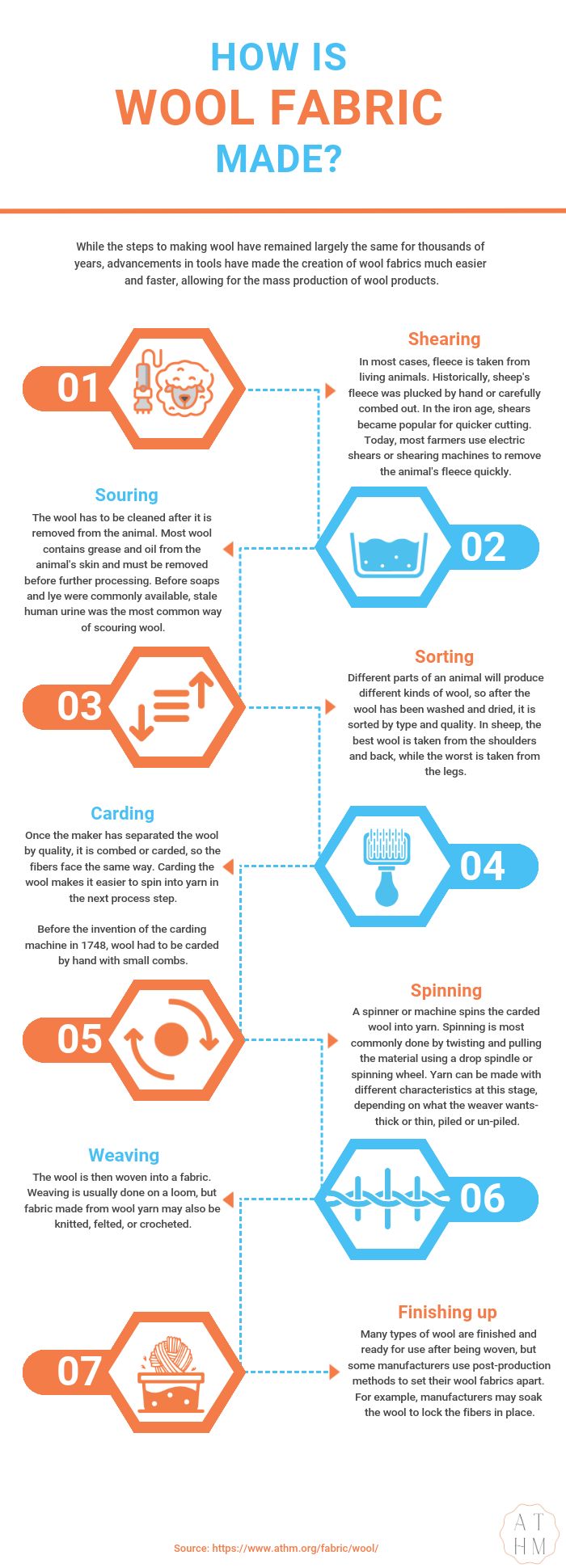

Where Is Wool Fabric Produced?

Wool is primarily produced in Australia, China, the United States, Russia, New Zealand, Argentina, South Africa, the United Kingdom, and Uruguay. However, it is also made by small farms all over the world.

According to WoolMark, Australia produces nearly 25% of the world’s wool annually- more than 345 thousand tons. Australia is home to 68 million sheep and more than 60,000 wool farmers. The vast majority of wool that Australia produces is Merino.

China produces roughly 18% of the world’s wool, or 260 thousand tons. Most Chinese wool is used for industrial purposes, like rugs, fire retardant materials, and insulation.

The United States produces nearly 150 thousand tons of wool each year. Most of the United States’s wool is made in Texas, though much wool is also made in California, Wyoming, Colorado, and Utah.

How Much Does Wool Fabric Cost?

The price of wool fabrics varies wildly, even if they’re the same type. Cashmere, for example, can cost anywhere from $50/yard to $250/yard.

On the other hand, Merino wool can cost anywhere from $20/yard to $50/yard.

What Certifications Are Available for Wool Fabric?

Certifications are an essential tool for consumers to identify eco-friendly or cruelty-free products. As with any textile, Wool fabric has certifications that signify to consumers the quality or sources of the material.

Responsible Wool Standard Certifications

The Responsible Wool Standard (RWS) is a voluntary international certification for farmers to show consumers that they made their products with responsible practices. The RWS is designed to protect animal welfare as well as the environment.

The standards also ensure that manufacturers and producers track the chain of custody so certified wool is never mixed with non-certified wool.

Wool Grading

While the RWS ensures that wool is ethically sourced, wool grading ensures the quality of wool for consumers. A few different grading systems are used, but the micron system for grading wool is the most common internationally.

The micron grading system is simple, as it is just a measure of the average diameter of a fiber. The smaller the diameter, the finer the wool is.

For example, Border Leicester wool usually has a diameter of 38-30 microns and is used for thick outer garments and industrial purposes. In comparison, grade A cashmere has a diameter of roughly 14 microns and is one of the most coveted fabrics for apparel.

What Is the Environmental Impact of Wool Fabric?

As with any modern material, wool has many negative environmental impacts. Because it is taken from livestock, greenhouse gases are a significant concern for wool production. Sheep- and the grass they eat- also require enormous amounts of water to produce.

Still, wool is one of the more environmentally friendly fabrics available. Fleece regrows on sheep each year, so it’s inherently sustainable. It does not require the slaughter of animals, is biodegradable, and doesn’t shed microplastics like many other synthetic fabrics.

Though many animal activists propose that wool production harms sheep, sheep must be sheared for their safety. If left untrimmed, many sheep overheat in the summer months.