Linen is a fabric woven from the flax plant and commonly used for clothing and housewares. Linen fabric is breathable, durable, absorbent, and can be soft to the touch. As a fabric made from a plant, linen is an eco-friendly material. Perhaps the oldest manufactured fabric, records of linen textiles have appeared in pre-historic cave dwellings in the Caucasus mountains and were estimated to be 38,000 years old. Today, linen is largely produced in Europe and Asia, and pure linen still offers the same strong material for clothing and housewares it provided in the days of the Stone Age.

What is Linen Fabric?

Linen is a fabric woven from the flax plant that is durable, sturdy, lightweight, and breathable. Linen gets its name from the scientific name of the flax plant, Linum usitatissimum. The sturdiness of linen stems from the flax plant having longer cellulose fibers than cotton. Weavers create a looser weave when creating linen to help soften the feel of the fabric. The resulting textiles are lightweight materials that can last for years.

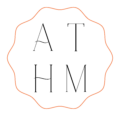

History of Linen Fabric

The earliest history of linen dates back 38,000 years, evidenced by scraps of linen fabric found in Caucasus cave dwelling. Mentions of linen occur throughout history, including an occurrence in a Sumerian poem thought to be the first love poem ever written, dating back to about 2,000 BCE. Gilgamesh, the king and protagonist in The Epic of Gilgamesh, the oldest extant piece of literature in the world, wears linen several times during the story. Linen also gets mentioned several times in the Bible (followers wrapped the body of Jesus in it).

Properties and Characteristics of Linen Fabic

Today, linen often seems like a high-fashion fabric. Either that or people complain that it wrinkles easily. But the truth is that it’s a utilitarian textile that brings strength and breathability to the garments made from it. In many ways, linen is far superior to other fabrics.

These qualities stem from the weaving pattern. Because flax fibers are a little tougher to work than cotton fibers, a tight weave is much more challenging to achieve with them.

Instead, we get a weave pattern that’s relatively loose when compared to cotton. That looser weave lends as much to the characteristics of linen as the fibers used in it. The weave and the fibers mean that linen fabric is:

- Absorbent: Flax is a hydrophilic fiber, which means it absorbs water well.

- Breathable: Linen’s loose, open weave allows for ample airflow around the body, which explains why cultures in hotter climates, like the ancient Egyptians, prized the material.

- Fast-drying: Clothing made from flax absorbs water, and when woven into the characteristic loose weave of linen, that water will quickly evaporate.

- Hypo-allergenic: Dust, pollen, and other allergens have less tendency to get caught in linen’s loose weave, and the fibers have antibacterial and antimicrobial properties.

- Moisture-wicking: Combining two of the above characteristics— it’s highly absorbent and dries quickly— gives linen moisture-wicking properties, actively drawing moisture away from the body. Since sweat carries excess heat from the body, the faster it gets removed, the quicker the body cools.

- Strong: Flax fibers break much less easily than their cotton counterparts. The hydrophilic nature of the material also means that with each wash, linen fabric gets a bit stronger, whereas other fabrics begin breaking down when exposed to water.

- Sustainable: The flax plant leaves no waste in that we can use its stems, flowers, and seeds. It also uses significantly less water to grow the crop than cotton, so linen dresses are more environmentally friendly than cotton ones.

- Does Not Pill: Strong fibers don’t break off and ball up in those tiny fuzz balls many of us pull from our sweaters during cooler weather.

- Does Not Retain heat well: The open weave that makes linen a cool, breathable fabric is ideal for summer clothing as it will allow significant heat loss during cooler weather.

- Does Not Stretch: The fibers don’t have the elasticity of cotton owing to the longer cellulose fibers in them. It makes for a stronger material, but a material with little give. Anyone who’s tried to put on a linen pullover shirt that’s just a little too small knows this very well.

Types of Linen

While linen covers a specific type of fabric (and, as mentioned above, sometimes includes materials that are only similar to linen), there are different types of linen— sort of like sub-categories. They include damask linen and varieties of weave patterns.

Damask Linen

Damask linen offers an ornate pattern in its weave. It’s also reversible. We often find this linen type used in tablecloths or decorative fabrics. A damask weave is relatively tight, making for a strong fabric.

On the other hand, the tighter weave, along with the woven pattern, makes for a stiffer feel, so damask linen doesn’t often appear in clothing. It is a standard fabric for ornate tablecloths since it offers the strength of linen fabric with the subtle beauty of something much more delicate.

Sheeting Linen

Sheeting linen has a tight weave like a damask, but it doesn’t get woven into a decorative pattern, so it retains a softer feel. While loosely-woven linen appears in some clothing items, sheeting linen has a closer knit, so it’s sometimes referred to as close-knit linen.

Unlike damask, sheeting linen is often plain and unadorned. Bedding made from it is quite soft and will last much longer than cotton sheets.

Loose Weave Linen

Loose weave linen brings the most breathability of all the linen to the garments made from it, but with a looser weave, we sacrifice some of the linen’s strength. With more significant gaps between fibers, the material can snag more easily.

While a shirt from loose weave linen isn’t unheard of, this linen often gets augmented with cotton or other fibers for a blended material that brings more durability than a 100 percent loose weave linen garment.

Plain Weave Linen

Plain weave occupies a Goldilox zone between close and loose weaves. It’s highly absorbent, so you’ll often find that linen napkins get made from this. It can also have a softer texture than other types.

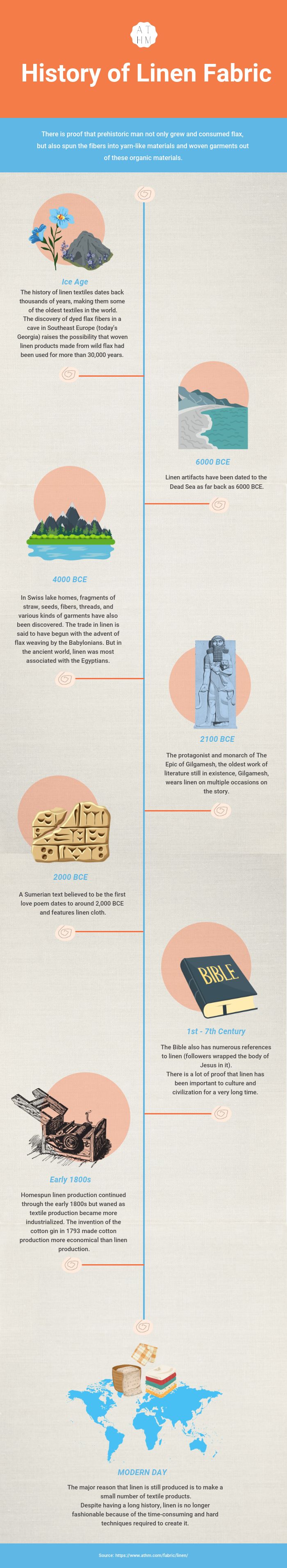

How Is Linen Made?

From planting seeds to donning your linen suit on a warm summer day, a lot needs to happen to create the breathable, durable linen fabric that so many of us love to wear and use. The quality of the final product depends on actions taken during each step, so farmers using more meticulous methods produce higher-quality linen fabric.

Its labor-intensive production process makes it more expensive than materials like cotton or some synthetic fabrics. As a result, the automation and mechanization of plant harvesting and fabric weaving have marched on and made those other fibers less expensive. They don’t apply well to the production of linen, so its prices have not seen the same decrease as other textiles.

Planting (and Growing) Flax

Like any crop, flax must be planted and cultivated if you want to grow it in large quantities. As a plant that doesn’t do well with extreme heat, it needs a cooler environment to flourish, so farmers in hot climates must wait until cooler months to plant.

In many places, the plant is a winter crop.

Harvesting

After about 100 days, flax is ready for harvest. Once the stems start to yellow, harvesting is in order. Harvesters must pull the plant up from the roots as the fibers extend down. Cutting the plant off at ground level leaves valuable fibers in the ground.

However, there exists no reliable way of doing this mechanically, so to get the best fabrics for linen, flax must be hand-harvested, which is one factor driving the higher prices of better-quality linen.

Drying, Threshing, and Retting

Flax must dry out after harvesting, so the crop sits in the open air for several weeks. After that, workers thresh the stalks to remove seeds.

After these processes finish, it’s time for retting, which involves soaking the fibers in water. Since the fibers used in linen are bast fibers (sometimes called “inner bark”), we use water and the accompanying bacteria to break down the parts of the flax we need to remove to obtain the fibers we want for the linen.

After the retting soak, the flax is dried again, then cured by storing it for several weeks.

Spinning Flax Into Yarn

From here on out, the process resembles the manufacture of many other fabrics. The fibers are spun into yarn using a distaff, a tool that keeps the fibers from tangling as they’re twisted into yarn and wrapped onto a bobbin.

Weaving

Weavers use a loom to interlock the yarn along the X and Y axes. At this point, they may also create patterns during the process for a decorative piece of fabric, or the weaver may create a tighter, plainer weave for use in clothing.

How Is Linen Used?

The early use of linen fabric was for undergarments, so it hasn’t always been a luxury item. However, it’s usually a clothing material or at least a homewares item. We find it in tea towels, different types of upholstery, and a range of wardrobe items.

In days gone by, linen fabrics found other uses beyond clothing. For example, it was used as rope, featured in bags, and used for fishing nets. The material’s durability lent it the strength you’d want in those items. After all, a rope made from cotton would be more likely to snap while rappelling from the inside of a giant wooden horse on your way to kill some Trojans.

Linen also had some protective attributes ascribed to it in ancient times since flax was said to offer some protection against magic and witches. Also, since Jesus was wrapped in linen upon his death, many cultures ascribed it to the flax, believing it had protective powers.

Some European cultures put flax and linen in coffins to ward off ghosts.

Advantages of Linen

A good deal of the characteristics of linen listed above translates directly to advantages.

- As the fabric wicks moisture from the body, pieces of linen clothing help actively cool the wearer.

- Flax fibers’ strength makes linen fabric strong, so anything getting regular use, from tablecloths to towels to rope, will stand up to use and last a long time.

- Its absorbency lends itself well to drying things, as in a towel or napkin.

- Linen’s natural fibers make it hypo-allergenic, so bath towels, bedding, and clothing will present less risk of allergic reaction than other materials.

- The breathability linen brings to a garment makes it comfortable and versatile as a clothing fabric, especially in warmer weather.

Disadvantages of Linen

While we’ve discussed linen’s strength at length, many people think of linen as a delicate fabric or at least one that’s not easily cared for.

The truth is that while linen fabrics are, depending on their weave, strong and durable, that doesn’t mean that skirts made from linen will always look fantastic. Linen lasts, but it will last longer if cared for properly. Unfortunately, proper care can be time-consuming.

- As a summer textile, linen makes for clothing unsuited for year-round wear. Your wardrobe will have some gaps in it during colder seasons without the linen pieces you wear in the summer.

- Creasing. Anyone who’s worn linen shirts for more than a two-minute ride noticed quickly how wrinkled the garment got in a short period.

- Ironing linen fabrics takes time. Due to linen fibers’ chemistry, a dry iron won’t do much to smooth the material, at least not without a lot of time and effort. Steam ironing works best, but for best results, you’ll want to dampen the clothes a few minutes before ironing.

- Laundry issues. Improper washing techniques might not destroy a linen garment, but they can make it look worse than you wanted it to look. Low temperatures and gentle detergents are the orders of the day.

- Linen fabrics aren’t cheap. The complicated and labor-intensive processes of harvesting, preparing, weaving, and sewing with linen make for higher costs.

- Linen is tough to sew. Once you cut linen fabric, the threads form a fringe, and sewing in details must be done with this fringe in mind and treated properly.

Alternatives to Linen

Any alternative to linen may allow you to avoid these disadvantages, but you’ll also lose out on the durability and the feel of natural fabrics.

Cotton finds use as a linen substitute, even getting marketed as linen-style material. Manufacturers weave the fibers into a larger, more open weave pattern for the appearance of linen.

Other substitutes include synthetic fabrics like rayon that mimic the light feel of linen fabric but will not have the same breathability or sturdy constitution.

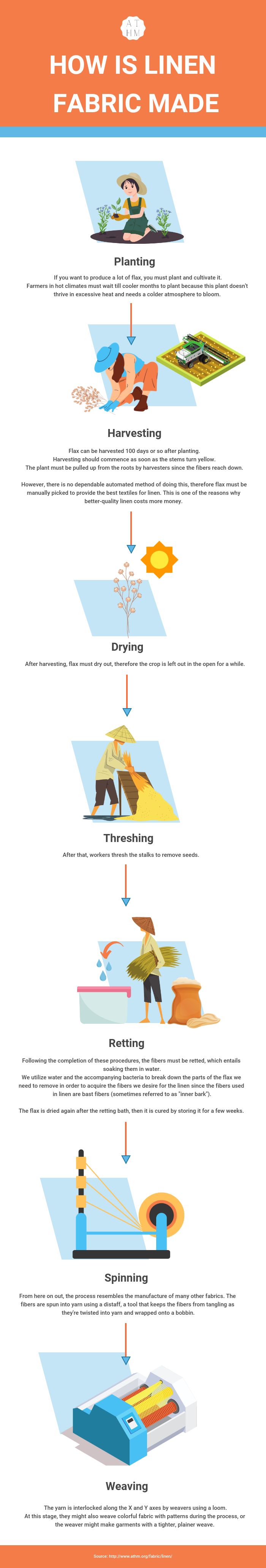

Where Is Linen Produced?

More than half of the world’s flax yarn comes from China. Italy, led by Milan Fabrics SRL, produces more than five million square miles of flax fibers, making it the world’s second-biggest exporter.

Tunisia and Lithuania round out the world’s top four linen producers. Aside from boutique-style weavers, there is no commercial manufacturer of linen in the United States.

Ireland used to be the mecca for the world’s finest linens, but that was during the 19th century when linen was much more common in clothing than it is today.

How Much Does Linen Cost?

Sold by the yard, linen usually comes on a bolt, and it’s cut from a 42″ x 100-yard piece of fabric. So one yard of fabric would measure 42″ x 36″. Pricing varies greatly, though you’ll be hard-pressed to find 100 percent linen for less than $8 per yard.

More intricate weaves, higher-quality linen, and any patterns you might look for will cost more than a plain piece of loose-woven linen. And using a linen blend, say linen combined with cotton, won’t necessarily make for a less-expensive piece of material.

For instance, you can find 100% Linen Fabric on Amazon.com for under $10 per yard. You can expect to pay about twice that price for a tighter weave.

What Certifications Are Available for Linen?

Like anything else, linen manufacturing requires some oversight, and the resulting products can be certified so customers know what they’re getting. There are three main certifications linen can carry.

European Flax Certification

Linen carrying the European Flax Certification comes from Western Europe— specifically, the Netherlands, France, and Belgium. The certification process stands to demonstrate transparency in the linen production process, as well as environmental stewardship by manufacturers.

This certification carries the message that the certified linen, from the planting of the first seed to affixing a clothing label to the finished garment, involves local farmers, no waste, and no chemicals. Manufacturers must have also employed fair labor practices for linen to receive this certification.

Global Organic Textile Standard

The Global Organic Textile Standard takes the European Flax Certification ideals worldwide. Manufacturers cannot employ harsh chemicals at any point in the manufacture of linen to receive this certification, and laborers must have safe and fair working conditions.

OEKO-TEX Standard 100 Class 1 Certification

While OEKO-TEX Class 1 certification covers entire garments and includes certification of buttons and zippers, for example, it offers an assurance that materials have been tested and deemed safe.

Linen certified under this standard contains no banned compounds like heavy metals or certain chemicals that others might use in some textile processing.

A Class 1 Certification guarantees that the certified materials are safe, even for infants.

What Is the Environmental Impact of Linen?

Linen’s sustainability is key to its minimal impact on the environment. To begin with, flax’s ability to grow even in poor soil means it takes much less water to grow than other natural fabrics used in clothing. However, that’s just for starters.

- Linen’s durability means less clothing waste in landfills because it gets discarded much less often than other fabrics.

- Because it’s an organic material, biodegradability means it doesn’t clog landfills for hundreds of years like some synthetic fibers once linen gets discarded.

- As mentioned above, since every part of the plant can get used, a responsible flax farmer can produce fibers, seeds, and flowers from his plants while creating zero waste.

- Flax plants consume carbon dioxide at a high rate, thus lowering the carbon footprint of the farmers who raise it; wearing linen clothing supports lower CO2 atmospheric levels.

Final Thoughts

Linen fabric made a name for itself as a versatile, practical textile in early history. With advances in manufacturing, other cloths have proven to be less expensive, but recreating the full advantages of pure linen has proven difficult for synthetic substitutes.

Linen brings an environmentally conscious fabric with strength and durability to items ranging from hand towels to bedding linen to skirts and jackets, all of which can bestow a stunning look on the wearer.