Chenille fabric is a type of fabric that is made from rayon, cotton, silk, or acrylic fibers. The fabric is known for its softness and its ability to hold shape well. Chenille fabric was developed in France during the 18th Century. It’s a super supple fabric, most commonly used for comfy home textiles, like blankets, quilts, bedspreads, and chenille upholstery fabric.

The fabric is relatively new, less than 300 years old, but it’s evolved a lot to become the lovely fabric it is today. Consider this your comprehensive guide to chenille fabric, including its rich history, various uses, and distinct characteristics.

What Is Chenille Fabric?

Chenille fabric is a tough material with a softness, fuzziness, and slightly ribbed appearance. It has tufted yarn, creating the fuzzy texture and unique feeling of the fabric.

To achieve its distinctive characteristics, the yarn piles on top of one another, using two yarns to wrap around one and create the appearance of thicker stripes.

It is typically a synthetic fabric, even though it does use some natural materials. Chenille fabric uses either silk, cotton, or wool but often has some mix of synthetics, typically polyester or acrylic. Only a few products use 100% natural chenille, usually made with cotton.

Most varieties use a combination of acrylic yarn with cotton yarn. Depending on the materials used, the chenille fabric may have a feathery feeling or something slightly rougher.

The synthetic makeup contributes to the durability, so it can resist wear and tear for years while still being soft and comfortable. For this reason, it’s one of the most popular fabrics in upholstery and household textiles. In addition, chenille is used for clothing, typically dramatic shawls, evening wear, and costumes.

Chenille is becoming more popular in the fashion industry while still making up many household textiles, most commonly quilts or heavy drapes.

If you have an old soft throw or quilt passed down from your grandparents, it’s likely chenille fabric.

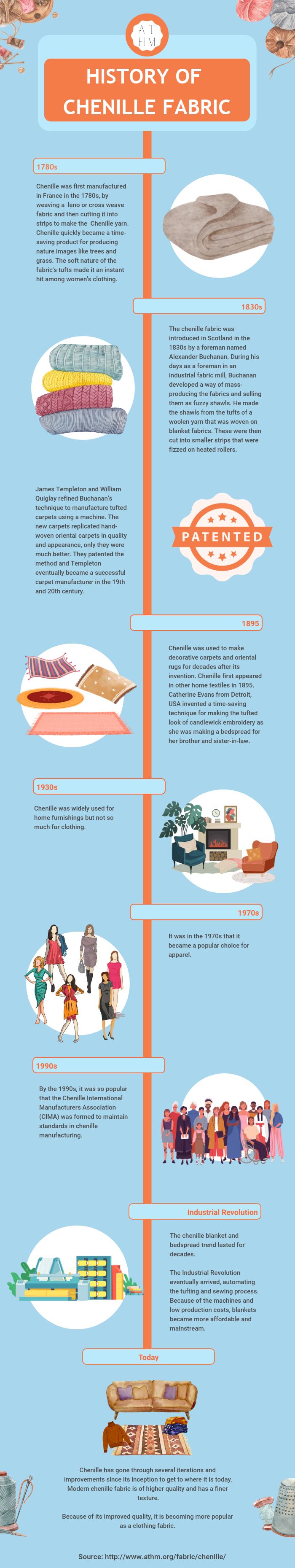

History of Chenille Fabric

Chenille came about around the 1780s, but many mistake the origination of this thick fabric. Alexander Buchanan, a foreman in a Scottish fabric mill, often gets credit for creating this fabric. However, he only introduced it to Britain.

Decades before Buchanan used chenille, it was in French clothing and other textile products. But there is no record of who created chenille in the country, so Buchanan is often the only name attached to this fabulous fabric.

But the name, “chenille,” is the French word for caterpillar, so it makes sense it originated in France. Nevertheless, Buchanan helped promote the fabric by using it to create stunning, feathery shawls that draped beautifully and kept the wearer warm during cold weather.

During this period, chenille fabric went through heated rollers to prevent frizz, but it could still be a messy fabric with many imperfections in the weave. James Templeton and William Quigley refined the process to make sturdier piles. These two earned a patent for weaving the cords more evenly to make chenille carpets.

For decades after their innovation, chenille created decorative carpets and oriental rugs. In 1895, chenille began to work its way into other home textiles. A young woman named Catherine Evans wanted to create a rich and luxurious bedspread and decided to with chenille fabric.

Soon after, other women began creating similar tufted blankets and quilts. Middle and high-class people appreciated the delicate embroidery of some chenille quilts.

Still, simple blankets and bedspreads were also affordable to even the poorest families. Besides their practical usefulness, these blankets created opportunities for struggling families to increase their income by tufting material and selling it.

The chenille blanket and the bedspread trend continued for decades. Eventually, the Industrial Revolution came, automating the tufting and sewing process. The blankets became more affordable and mainstream thanks to the machines and low cost of production.

Since its invention, chenille has gone through several iterations and improvements to reach where it is today. Modern chenille fabric is of higher quality and has a finer texture. The improved quality is why it’s becoming more popular as a fabric for clothing.

Properties and Characteristics of Chenille Fabric

Chenille has several desirable properties that make it ideal for particular textile products.

Iridescent

An unexpected characteristic of chenille is its iridescence. Usually, iridescent fabrics utilize iridescent threads and fibers, but chenille’s appearance is a trick of the light.

The striped pattern of the weaving technique makes the fabric look different from various angles, leading to the whimsical iridescent look.

When used for upholstered furniture or making window drapes, the fabric will change as the lighting in the room ebbs throughout the day, offering a magical transformation.

Draping Capabilities

Despite the fabric’s thickness and durability, it offers impeccable draping, making it an excellent choice for products like curtains or dresses.

It’s often utilized in costume-making and evening wear because it can create dramatic drapes with showstopping movement. Chenille delivers a slinky drape that almost wiggles when one moves but still looks elegant and luxurious.

Fuzzy Texture

One of the best properties of chenille is the fuzzy caterpillar texture that is soft and feathery. The textured quality is the most loved aspect of the fabric, making it cozy for sweaters, blankets, bedspreads, shawls, and jackets.

The feathery feeling is thanks to the two core yarns that create tiny loops around the single yarn. It has a 3D appearance often compared to a soft caterpillar.

Abrasion-Resistant

One of the most notable characteristics of chenille is its durability. In this case, durability mostly means abrasion-resistant, so it can handle lots of wear and tear, making it ideal for frequently used furniture or high-traffic carpets.

Absorbent

Chenille is an immensely absorbent fabric, meaning it’s ill-suited for outerwear on rainy days. It soaks up liquids and holds them. While this characteristic is not ideal for clothing, it is the desired quality in a bath or hand towel.

Types of Chenille Fabric

Chenille can use a variety of fibers, like wool, silk, rayon, polyester, and so on. These varieties are “silk chenille” or “wool chenille.” Aside from those, there are two types of chenille fabric.

Utility Chenille

Utility chenille is rare because it’s a 100% natural fabric. It is for more delicate products, like baby clothes, bathrobes, and bath towels. This type of chenille uses 100% cotton fibers to create the chenille yarn and fabric.

Unsurprisingly, utility chenille is more expensive and sometimes less durable. But cotton is still a resilient fabric, meaning this kind of chenille can still handle general wear and tear.

Home Decor Chenille

Home decor chenille fabric is the more common variety. It works for almost anything, from dresses and rugs to upholstery fabric and scarves.

In addition, chenille is frequently used as a drapery fabric. Home decor chenille is more durable because it features synthetics that make the tufted weave stronger.

How Is Chenille Fabric Made?

The key to making chenille fabric is the weave using three yarns. To create this tufted yarn, piles of small loops build up around the single yarn in the weave.

It took decades for this process to be standardized, as people used to vary the weave based on their habits and knowledge. But now, all chenille fabric uses the following process for production:

- First, one has to make the chenille yarn. A short fiber goes between two core yarns and twists together to make a strong thread for weaving.

- Once the yarns are wrapped and form the tiny loops, they are cut into strips to create the pile and texture of chenille. Sometimes, these piles come loose, so they must be “glued.”

- Low-melt nylon makes up the yarn’s core. Once the strips are cut and the piles created, the manufacturer steams the strips to lock the tufts into place with the heated nylon.

- When the chenille yarn is ready, it can be woven into the chenille fabric. A specific weave is used, often called the pile weave or chenille weave.

How Is Chenille Fabric Used?

This section will dive into the many ways the textile industry utilizes this fuzzy fabric.

Upholstery

One of the most common uses for chenille is upholstering furniture. Upholstery fabrics must be durable, thick, and easy to manipulate. Chenille checks all the right boxes, leading to its usage being widespread.

Moreover, chenille is soft and pleasant, making it ideal for comfy couches or relaxing armchairs compared to rougher alternatives.

Carpets and Rugs

Chenille’s history comes from rugs and carpets. Many fabrics cannot handle constant foot traffic, but chenille is durable enough to last years, even in heavy duty areas.

In contrast, a velvet rug would be vulnerable to abrasion and likely lose its fuzzy texture and elegant appearance after just a few months. Chenille carpets have a plush and supple texture, making them cozy on your feet and attractive in your home.

Blankets and Quilts

Quilting is one of the most popular uses for chenille fabric. Toward the end of the 1990s, chenille became a top material choice for making quilts because of its appealing texture and resistance to wear. When stitched into the backing of fabric, it creates a velvety smooth appearance.

Another use of chenille in quilting is “ragging.” This term refers to loosening the yarn around the seams of a blanket or quilt.

While this technique may appear messy to some, many quilters appreciate the casual country look it gives their pieces. Quilts with ragged seams are known as “slash quilts” or “rag quilts.”

Clothing

One of the most identifiable uses for chenille in garments is on Letterman jackets, part of the classic jock look for high school and college athletes.

It usually has a soft torso, made from chenille, with a more durable sleeve material, like leather. Chenille is an excellent choice for this type of jacket because it’s tough but creates a lovely contrast between soft and hard.

Aside from Letterman jackets, chenille is used to create fuzzy shawls, which were the first use for the fabric in the 1800s.

Chenille fabric works for dresses, eveningwear, blouses, pants, costumes, and more. Many people in the textile industry see it as a comfortable but affordable fabric with outstanding durability. Given that, several designers use it for high-end clothing.

Advantages of Chenille Fabric

Chenille fabric has many advantages. You can read about the top five benefits below.

Durable

As mentioned, chenille is a highly durable fabric despite its soft and supple texture. Other materials with comparable textures can easily snag and wear, but chenille is tough and long-lasting.

For this reason, it’s frequently used as upholstery materials, and for certain outerwear garments. However, chenille isn’t perfect. Yarns can loosen, which will be discussed further in the disadvantages section below.

Fuzzy and Feathery

Chenille has a fuzzy and feathery appearance and texture that is comfortable for wearing or having in your home. The texture is thanks to the distinct weaving technique where two yarns encircle one and create a raised texture of soft yarns.

Sometimes, the excessive fuzziness can look messy, but this adds to the charm and casual vibe of the fabric. As the name indicates, chenille has a similar texture and appearance to a fuzzy little caterpillar. It is not nearly as sleek and even as other fabrics, such as velvet.

Soft Draping

Despite the fabric’s thickness and durability, it’s a beautiful drapery fabric, making it suitable for gowns and shawls. It tends to flow while holding desired shapes and boasts a more iridescent appearance.

Chenille has a very loose yet weighted drape, so it doesn’t have an airy, breezy drape. Instead, it features a luxurious and weighted drape that looks expensive and elegant.

Iridescent

A surprising characteristic of most chenille fabrics is the iridescent quality, giving it a lovely sheen. The iridescence comes from the uneven weave because two yarns go in one direction while another goes the other way.

This contrast results in a slight 3D effect, with light catching the two angles of yarn differently. Chenille can have an iridescent appearance even if no iridescent fibers or yarn is in the fabric.

Decent Heat Retention

Not only is chenille soft and cozy, but it can keep you warm in the winter! Alexander Buchanan was onto something brilliant when he decided to use this material to craft shawls. And Catherine Evans recognized the fabric’s heat retention capabilities, making it perfect for blankets and chenille bedspreads.

Chenille is an impeccable cold-weather fabric but can be overwhelmingly warm in the summer and springtime. However, that quality means chenille can help insulate your home as a window treatment, lowering energy costs and keeping your home warmer.

Disadvantages of Chenille Fabric

All fabrics have downsides, and chenille is no exception.

Tufts Can Loosen

The distinct weaving style of chenille makes it susceptible to loose tufts, which cause bare patches where there is no fuzzy texture or distinct lines. For the most part, loose tufts are only an issue for homemade quilts or garments.

A few years after the chenille’s invention, manufacturers began using low-melt nylon in the core of the yarn to set the piles in place. To do this, producers steam (“autoclave”) the hanks of yarn, essentially gluing them in place with the melted nylon.

Color Can Fade

While chenille is a durable fabric that can resist abrasion, it isn’t as wonderful at holding its color. Dyed chenille can fade in the sun or over time.

The fade is slow, but years of use and sunlight will result in your chenille products losing some of their hue and vitality. That fade extends to chenille washed in warm or hot water, which can draw the dye out quickly.

Can Stretch or Shrink

Because of the distinct tufted weave, chenille yarn can shrink or stretch if not cared for properly. Wet chenille can easily stretch out, never returning to its former shape. This often happens when the fabric is washed and then hung to dry.

Because the fabric is heavy, the yarns will stretch downward, causing the piles to separate. In many cases, this reaction can diminish the fuzziness and ruin the form of the item. And yarn dried at high temperatures can shrink, piling the tufts closer together and tightening the yarn.

Challenging Maintenance

As you can see from the two disadvantages above, chenille must be handled with care if you want it to last. Its specific needs can frustrate many people, especially as it’s described as a durable fabric. There’s no question that chenille is durable, but it just needs a little extra care and attention when you want to wash it.

In general, it’s recommended you have chenille items dry-cleaned or professionally washed. Manufacturer care instructions even recommend never washing chenille unless you have to, to avoid damage.

Chenille must be hand washed or machine washed on a delicate cycle in cold water. After that, it needs to be either dried flat or machine-dried on the lowest heat setting possible. A low-heat machine wash is ideal, as air drying in the wrong position can stretch out the fabric.

Alternatives to Chenille Fabric

If chenille doesn’t sound like the right fit for you, below are three alternatives that may suit you better.

Velvet

While velvet does not have the ribbing or durability of chenille, it does offer a super fuzzy, feathery texture paired with a gorgeous drape. Velvet can also be easier to manipulate, especially when making complex garments, like costumes or evening gowns.

As a chenille alternative, velvet works best in clothing, such as shawls or scarves, because it has a similar weight, drape, and supple texture. However, for upholstery fabric and other household textiles that should be more durable, velvet is not a suitable option.

Corduroy

If you want to utilize the characteristic look of lines on chenille fabric, corduroy is your best bet. Corduroy has deeper ribbing than chenille, but the two fabrics share a similar velvety smooth texture on the lines.

Corduroy is stiffer than chenille, leading to it being difficult to drape or manipulate into garments. But for upholstery and many other household textiles, it offers the same durability and soft feel as chenille.

Taffeta

Taffeta can be a decent replacement for taffeta, especially when making clothing. It has a similar thickness and can drape like chenille. However, it does not have the fuzzy texture or the appearance of lines that chenille does.

A significant characteristic the two fabrics have in common is their iridescence, which is subtle but stunning. Taffeta tends to be slightly shinier, but when making evening gowns or costumes, taffeta is an excellent choice.

Where Is Chenille Fabric Produced?

Unlike most fabrics, chenille fabric comes from all around the world, including France, the United States, Scotland, Australia, and more.

What Certifications Are Available for Chenille Fabric?

Below are the certifications available for chenille fabric, depending on what fibers were used to produce it.

Global Recycled Standard

The Global Recycled Standard certification is given to textile manufacturers who use recycled polyester and other synthetic materials.

Responsible Wool Standard

A Responsible Wool Standard ensures that manufacturers follow strict guidelines for the property treatment of animals.

Woolmark Certification

This certification concerns the quality of the wool fibers. Manufacturers must follow specific guidelines to produce the highest quality wool fabrics.

Silk Mark Certification

One of the most respected certifications in the textile industry, the Silk Mark Certification verifies that the fabric is 100% silk with no other materials. Manufacturers must also practice sustainability and respect any animals or people included in the process, like the silkworm insects.

What Is the Environmental Impact of Chenille Fabric?

As chenille is almost always synthetic, it does have harmful environmental consequences. The manufacturing of chenille fabric causes the following environmental impacts:

- Silk, wool, or non-organic cotton are unsustainable materials

- Silkworms, mulberry trees, or sheep may die in the chenille production process

- Production emits greenhouse gasses

- Requires land and water for cotton growth

- Chemical waste in water supplies from synthetic fiber production, like formaldehyde and alkylphenols.

Conclusion

Chenille fabric is one of the fuzziest and warmest fabrics, making it the perfect material for winter sweaters, outerwear, or cozy blankets.

While it sat on the textile industry’s backburner for a while, it’s slowly becoming more and more popular, thanks to its durability and impeccable comfort. Everyone should own a feathery chenille blanket to curl up with when the weather gets cold!