Denim is a heavy-duty cotton fabric synonymous with American workwear and fashion. While the material has become ubiquitous in casual fashion, it was initially discovered by accident by French weavers in the 17th century while they were trying to replicate another style of heavy fabric.

Denim is characterized by a twill weave, which creates a subtle diagonal ribbing that differentiates denim from other utility fabrics like cotton duck or canvas. The material is durable, stain and wrinkle-resistant, and easy to maintain. While the fabric originated in France, denim is now a global operation with factories in every corner of the world.

Today, we’ll take a deep dive into this fascinating fabric, including its history, how it’s made, its characteristics, benefits and disadvantages, and much more.

What Is Denim?

Denim is a woven textile fabric made from cotton fibers utilizing a twill weave. The twill weave creates the diagonal weave pattern, a primary characteristic of denim. It’s a warp-facing fabric, which means it’s woven by passing the weft threads under two or more warp threads.

This style of weaving produces a fabric where the warp threads are most prominent. These threads are typically dyed while the weft threads are left white, giving denim its characteristic pattern.

Denim fabric, also known as jeans or dungarees, was initially created as a workwear fabric. However, the material was first popularized in America by the Levi Strauss company, a brand so synonymous with denim that people will often refer to denim as Levis.

Through the years, it’s transcended its position as workwear, and today it’s among the most fashionable textiles. This practical fabric can be seen everywhere, from jeans to shirts to accessories.

History of Denim

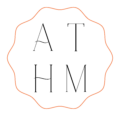

Weavers in France first discovered denim during the 17th century. The weavers tried replicating the pattern for another heavy utilitarian fabric called serge. While this practical fabric was quite similar, there was a slight change to the diagonal weave pattern, resulting in a piece of entirely new material.

During this time, new materials were named for where in the world they were produced, and so the weavers called their new creation “serge de Nimes,” which translates to serge from Nimes, which is the location in France where the fabric was first made. Over the years, serge de Nimes was shortened to de Nims and, finally, to denim.

A few hundred kilometers away in Genoa, Italy, Italian weavers produced a practical fabric similar to serge de Nimes. The material was used to make pants, skirts, shirts, overcoats, and countless other textiles, and the Italians called it “jean,” which was a shortening of the word Genoa.

The Innovations of Levi

Both denim and jean fabrics made their way to America by the 19th century, with denim used for the most demanding applications, such as mining, farming, and mechanical repairs. Then, in 1848, the world’s most famous jeans outfitter, Levi Strauss, made his way to New York from Bavaria and began selling dry goods with his brothers.

Shortly after, Strauss headed west, recognizing that the California gold rush was an excellent opportunity for the dry goods business. After all, these prospectors searching for gold would need sturdy and reliable clothing that could meet the demands of frontier life.

Strauss began selling denim goods in California, and his business steadily grew. Still, it wasn’t until 1873 that Strauss’ business would truly take off. Then, a tailor named Jacob Davis introduced himself to Strauss and suggested the addition of copper rivets to his trousers, which would reinforce a critical wear area and make the pants even more durable.

Strauss and Davis filed jointly for a patent for a denim workwear pant with riveted seams, which helped prevent the pockets from ripping away from the jeans with repeated wear.

Jeans in the 20th Century

The introduction of riveted seams helped Levi’s apparel empire grow exponentially. Still, everyone wore his garments exclusively as workwear, from gold prospectors to farm hands. It wasn’t until the rise of Hollywood and rock ‘n roll culture in America that jeans became a cultural phenomenon.

As James Dean and Marlon Brando began to make their mark on the silver screen, they did so in jeans. It didn’t take long for audiences to make the connection: if you were cool, you wore denim. At the time, the pants were still known as waist overalls, but this new generation of enthusiasts thought the trousers deserved a cooler name, and the name jeans took hold.

Blue jeans became a symbol of individuality, self-determination, and rebellion, and teenagers everywhere wore jeans. Denim’s cultural cache has never waivered, with each new generation putting its stamp on how jeans are worn and styled.

Properties and Characteristics of Denim

Denim is characterized by several properties that underscore its usefulness for both workwear and casual wear. The fabric is exceptionally versatile and can be made into clothing, textiles, footwear, and more.

The fabric is also incredibly durable and hard-wearing thanks to its twill weave composition, and its heaviness helps protect the wearer while preventing rips and tears.

Denim is a fabric that possesses many characteristics, which include:

- Breathability – The fabric is somewhat breathable, especially lighter or midweight denim

- Heat retention – Since it isn’t exceptionally breathable, it retains heat well

- Stretch – Spandex, lycra, or elastane can be added to denim to provide stretchiness

- Pilling – Highly resistant to pilling or bubbling

Types of Denim

Denim comes in a vast selection of styles, and anyone can find a particular type that suits their needs and price range. From clothing to shoes, accessories, and upholstery, denim fabric is ideal for any application. Denim types include:

- Sanforized Denim

- Washed Denim

- Raw Denim

- Selvedge Denim

- Colored Denim

- Waxed Denim

- Crushed Denim

- Stretch Denim

- Bull Denim

- Ecru Denim

- Organic Denim

Sanforized Denim

Sanforized denim goes through a mechanical process before it’s cut and sewn, where the fabric is pulled over hot rollers and placed in a dryer to shrink them. Essentially, sanforization is a fancy way of saying the fabric is pre-shrunk.

This process packs the threads together and dramatically reduces the shrinkage after washing. As a result, most of the denim sold today is sanforized, including many shrink-to-fit pairs.

Unsanforized jeans are favored by some enthusiasts, who appreciate the ritual nature of shrinking and breaking in their jeans.

Washed Denim

Washed denim is almost always sanforized, and it’s a category that covers virtually all blue jeans that are sold today. This fabric is cleaned in water before final processing to remove as much excess dye as possible.

The wash and rinse of denim may also alter the look of the fabric, which often possesses a characteristic pattern or worn appearance, such as stone wash, rinse wash, or acid wash denim. Most of these jeans are made from midweight denim and are softer than raw fabrics.

Raw Denim

Raw denim, also called dry or unwashed, receives no washing after it’s dyed and processed, and it’s also usually unsanforized. The raw nature of the fabric allows the wearer to impart a one-of-a-kind look and feel to their jeans, which will begin to show wear and fade over time.

Whether the raw denim is sanforized, it may shrink up to 20% after the initial wash. Raw denim fabric also bleeds a significant amount of color in the first wash, so you should wash raw denim garments alone.

Selvedge Denim

Selvedge denim features a striped finished seam edge that’s a contrasting color from the primary denim fabric. This fabric is woven on a shuttle loom, and selvedge is usually associated with high-quality denim.

While most denim is woven with a weft thread for each row, selvedge uses a single weft thread that is woven continuously through each row. This process provides a beautifully finished edge that doesn’t need to be sewn after production to prevent fraying.

The fabric is more time-consuming to manufacture, and most mills that produce selvedge fabric are committed to high product quality and a look and feel that’s true to the history of denim. Denim enthusiasts who cuff their jeans often prefer selvedge, as the contrasting hem offers a striking appearance.

Colored Denim

Colored denim refers to denim that isn’t blue. Blue jeans are dipped in indigo dye and are usually woven with white threads to create denim’s signature white-speckled appearance. Colored denim, such as black jeans, is processed with sulfur dyes to produce shades other than blue.

Waxed Denim

Waxed denim receives a treatment of a lightweight and flexible wax after weaving, which provides a water-resistant finish.

Waxed reverse denim has the wax application on the backside of the fabric, and it’s popular for outerwear and luggage applications. However, wax is sometimes applied to the front of the material instead, offering a high sheen look popular for fashion apparel and handbags.

Crushed Denim

Crushed denim is a mechanical and chemical treatment that lends a heavily wrinkled look to the denim fabric, which is popular for fashion applications.

Crushed denim has weft yarns that twist over the warp yarns during the weaving process. After washing and drying, the fabric crumples up, lending its crushed appearance. Chemical treatments and washes can further exaggerate and preserve the wrinkled appearance.

Stretch Denim

While all jean fabrics offer a small amount of stretch, denim can also be woven with synthetic fibers like spandex, lycra, or elastane, increasing the fabric’s stretchiness.

Stretch denim is popular for fashion applications because it enhances the wearer’s shape and is considerably more comfortable than denim without spandex. Stretch denim is common for slim-fit or skinny jeans.

Bull Denim

Bull denim is a heavyweight denim fabric. It’s popular for upholstery applications and outdoor goods. Bull denim has a 3/1 twill construction, which utilizes three warp threads for each weft thread. The resulting product is heavy and even more sturdy than regular weight fabric.

Unlike other fabrics, which are usually indigo dyed before weaving, bull denim is dyed afterward and available in many colors, and natural shades are generally the most common. As a result, bull denim is an excellent choice for curtains, outerwear, and upholstery applications.

Ecru Denim

Ecru denim is a fabric that is not dyed before or after weaving. This fabric is sold in its original off-white color and is popular for fashion applications.

Organic Denim

Organic denim is made from cotton fibers that have not been grown or treated with synthetic chemicals harmful to people and the environment. Organic denim is commonly processed to reduce the overall environmental impact of production, including how much water is used in processing.

How Is Denim Fabric Made?

Making the fabric is a fascinating mechanical process involving several steps before the finished fabric is ready to be made into garments or upholstery. Once cotton fibers have been processed into yarn, it’s ready for production.

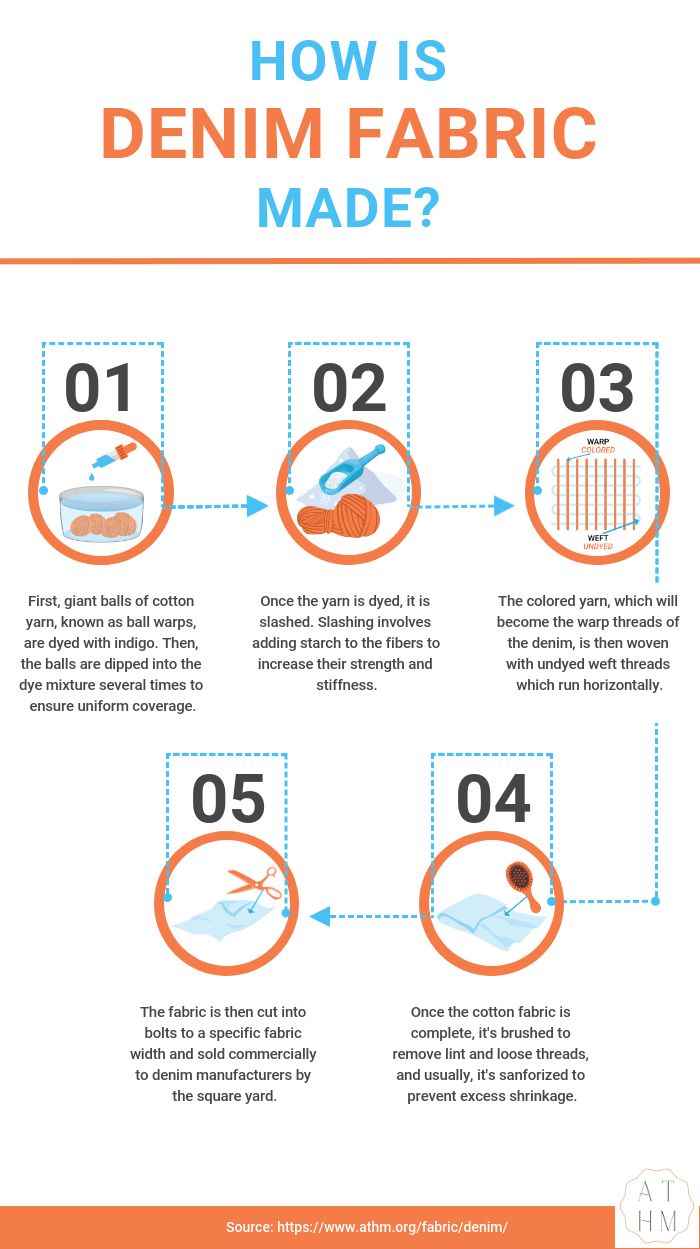

First, giant balls of cotton yarn, known as ball warps, are dyed with indigo. Then, the balls are dipped into the dye mixture several times to ensure uniform coverage.

Once the yarn is dyed, it is slashed. Slashing involves adding starch to the fibers to increase their strength and stiffness.

The colored yarn, which will become the warp threads of the denim, is then woven with undyed weft threads which run horizontally. Finally, a projectile loom weaves the weft and warp threads together to create denim fabric.

Once the cotton fabric is complete, it’s brushed to remove lint and loose threads, and usually, it’s sanforized to prevent excess shrinkage.

The fabric is then cut into bolts to a specific fabric width and sold commercially to denim manufacturers by the square yard.

How Is Denim Used?

We typically think of denim as a fabric for jeans, shirts, or jackets, but the uses for this fabric extend far beyond the apparel world to different types of products.

The obvious uses of this fabric are in the apparel world. Denim’s primary use is as a covering for denim jeans, shirts, and jackets. However, the fabric is also used for accessories such as hats, bags, and footwear.

It’s also a commonly used fabric for upholstery and popular material for producing curtains, chairs and couches, and lamp shades.

Once denim products have reached the end of their lifespan, they get recycled into new goods. Some brands offer recycled denim clothing, in which old articles get cut, cleaned, and resewn to create new products.

Fibers from the factory floor can easily be recycled into insulation materials for new homes and buildings. In addition, Levi’s recently launched a recycling campaign to turn old and unwanted jeans into new insulation. Ford Motors also uses recycled jeans as a carpet backing material in their cars to provide sound insulation.

Advantages of Denim

Advantages to denim include the following:

- Twill weave provides exceptional durability

- Wrinkle resistant

- Hides stains well

- Available in different fabric weights for all-season wear

- Excellent value for money

- Low maintenance and easy to care for

These advantages make denim a popular choice for everything from apparel to upholstery.

Disadvantages of Denim

There are several disadvantages to denim that you should keep in mind.

- Indigo dye can quickly transfer in the wash or onto other surfaces

- Production requires significant resources, and there are some environmental concerns

- The texture of the twill weave isn’t as soft or comfortable as some other fabrics

- The fabric fades and shows considerable wear over time

Alternatives to Denim

Alternatives of denim include the following:

- Corduroy

- Chinos

- Cargo pants

- Khakis

- Leggings

For people who find the disadvantages of denim jeans more troublesome than they’re worth, you may find these viable alternatives more attractive and appealing to use.

Where Is Denim Fabric Produced?

French weavers originally invented denim fabric, with similar fabrics coming from Italy. The vast majority of jeans production was in America until the 1970s. As global consumerism has grown, denim production has diversified significantly, with countries like China, India, Bangladesh, and Turkey accounting for more than 50% of global jean production.

While the desire for fast fashion has grown exponentially over the last fifty years, there’s still something to be said for artisanally made jeans. Japan, Italy, France, and the United States produce incredibly high-quality denim for the luxury consumer or denim enthusiast, albeit in much smaller quantities than the leading producers.

According to Statista, the leading exporters include:

- China – $2.2 billion

- Bangladesh – $798 million

- Pakistan $523 million

- India – $355 million

- Turkey – $274 million

- Hong Kong – $204 million

How Much Does Denim Cost?

The square yard price of denim varies significantly depending on weight, washes, and styles. Here’s what you can expect the price to be for different types of fabric at retail.

- 10 oz indigo wash – price: $13.20/yard

- 7oz indigo wash with spandex -price: $11.00/yard

- 10 oz bull – price: $13.92/yard

- 8 oz narrow railway stripe – price: $20.20/yard

- 4.5 oz Tencel – price: $14.88/yard

- 10 oz Japanese selvedge – price: $12.95/yard

- 14 oz Japanese selvedge – price: $14.95/yard

These are all approximate retail figures, and the price of cotton denim can differ significantly based on quality or production characteristics and whether you can secure bulk pricing.

What Certifications are Available for Denim?

As the fabric industry continues to emphasize responsible production and sustainability, many different certifications are available for denim fabric, which denote that the textile or garment followed strict environmental and ethical standards during production. Some of the most popular denim certifications include:

- Fairtrade Textile Standard – A standard for the entire textile industry that seeks to engage manufacturers and labor forces throughout the supply chain to provide better working conditions, wages, and environmental outcomes during production.

- Better Cotton Initiative – A collection of member companies committed to implementing higher production, sustainability, and social justice standards for producing cotton goods.

- Oeko-Tex Standard 100 – A testing and certification standard that tests fabrics throughout the production cycle to ensure environmentally friendly production and material free of chemical residues.

- Global Organic Textile Standard (GOTS) – GOTS certification is an international mark of quality assurance used worldwide to denote that a product is at least 70% organic and produced in a manner that is environmentally and socially ethical.

- Cradle to Cradle – A comprehensive label that shows the manufacturer is making efforts for eco-intelligent designs. Cradle to Cradle certification encompasses material choices, recycling initiatives, a focus on renewable resources, efficient water practices, and social responsibility.

What Is the Environmental Impact of Denim?

While denim can be a sustainable and biodegradable fabric, there’s much more to the environmental impact of cotton denim than meets the eye. The unfortunate truth is that production has a profoundly negative environmental effect.

The negative impact of cotton denim production begins in the cotton field. Growing cotton requires significant land, water, pesticides, and fertilizers. In addition, cotton requires significantly more water than other crops, with an estimated 1,300 gallons needed to grow a single pound of cotton.

Once the cotton is harvested and turned into yarn, the yarn is dyed to create the signature blue hue. Almost all dyes used are synthetic and produced from various chemicals. After dyeing, the cotton is washed to remove excess dye, which contains several pollutants that can negatively impact water sources and soil.

The weaving process requires a lot of electricity to run the machines that weave the cotton fibers into denim fabric. Once the material is prepared, the manufacturer uses more electricity and water in the washing process.

A recent study by Levi’s estimates that the production and use of a single pair of Levi’s 501 jeans utilize nearly 1,000 gallons of water from the growth of the cotton through to the care and maintenance of the denim by the end user.

Thankfully, an emphasis on sustainability and reducing the industry’s carbon footprint has led to some exciting new developments regarding production. While denim fabrics still require significant resources to produce, certification standards such as Oeko-Tex, Fairtrade Certified, and Cradle to Cradle are dramatically reducing the environmental impact of denim production.

Fast fashion retailers and inexpensive jean goods are unlikely to carry these production standards. Denim fans concerned with the environmental impact of the fabrics they wear will want to look for these certifications, indicating that the products were made as sustainably and environmentally friendly as possible.