Silk is a luxurious fabric that is known the world over for its comfort and quality. It has been used for centuries, and its history is as fascinating as the fabric itself. Royalty worldwide used silk as their fabric of choice, which continues to be a favorite fabric of the rich and famous. Even today, silk is associated with luxury, wealth, and high fashion.

But silk is more than just a piece of pretty fabric. It has distinct properties that make it unique among other materials. This article covers the rich history of silk, its characteristics, applications, and its impact on the environment.

What Is Silk Fabric?

Silk fabric is a natural protein fabric made from the protein fibroin. Fibroin is a protein that is secreted by certain insect larvae, such as “silk worms”. Silk has the distinction of being the strongest naturally occurring textile in the world. Despite its strength, silk is prized more for its softness and comfort. The softness of silk made it a prized fabric worldwide and led to it becoming a popular gift for a special occasion.

As a protein fiber, silk differs from other natural fibers like cotton and wool. The silk protein, also known as fibroin, also gives it distinct characteristics that make it a desirable fabric.

Silk is made from the cocoons of silkworms. The silkworm larvae spin these cocoons to protect themselves while transforming into adult moths. Once the moths emerge from their cocoons, the silk threads are harvested and weaved to make silk fabric.

The silkworm spins its cocoon by producing a silk fiber (fibroin). This fiber is made up of long-chain protein molecules that occur in a crystalline structure.

History of Silk Fabric

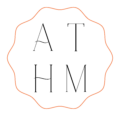

The first evidence of silk production dates back the 4th Millenium BCE in China, during the Yangshao Culture (Neolithic period).

Silk fabric quickly became a coveted item in China. In fact, it was so valuable that only the emperor and his family were allowed to wear silk clothes. In addition to wearing silk, the Chinese used it for writing and to signify their social class.

Silk fabric was confined to China for thousands of years. It was not until 114 BCE that China began exporting silk to other parts of the world via the Silk Road.

The Chinese kept the silk-making process a closely guarded secret for centuries, and for a good reason. Demand for silk was high globally, and merchants selling silk amassed great riches by trading the fabric with the rest of the world.

The Silk Road – 114 BCE

Beginning in 114 BCE China began exporting Silk via a network of trade routes that became known as the Silk Road. The Silk Road was not a single road, but a network of routes that stretched from present-day China to Southeast Asia, India, Central Asia, the Middle East, East Africa and Europe. These routes were very significant historically and facilitated the exchange of silk fabric, other goods, as well as culture, religion, and politics between the east and the west.

Silk fabric eventually made its way to Europe, rapidly becoming a much-coveted commodity. European royalty, in particular, fell in love with silk and began wearing it as a status symbol. Wearing silk clothes was a way of showing off one’s wealth and power. It was also a popular home decor.

The demand for silk accessories was so high that the Chinese began to worry about running out of the fabric. To counter this risk, the Chinese government imposed the death penalty on anyone smuggling silkworm eggs to retain their monopoly.

Despite China’s best efforts, silkworm eggs did make it to Europe, and silk production eventually spread to other countries.

The Spread of Silk Worms – 300 CE

Silk cultivation began to spread to other parts of Asia. Japan started raising its silk worms around 300 CE, and by 550 CE, silk production had spread to the Arabian Peninsula.

The spread of silk production led to a decrease in demand for Chinese silk. However, few nations knew how to produce silk that was as high quality as silk made in China.

The Crusades – 1095 to 1200 CE

It wasn’t until the Crusades that silk reached continental Europe. Silk made its way to the highest reaches of European society, driving demand for the fabric and the silk worms needed to produce it.

Europeans developed viable methods for raising silkworms in the Middle Ages. Several Italian states dominated silk production and quickly became economic powerhouses during this time.

The Renaissance – 1300 CE

During the Renaissance, several new silk and textile technologies, such as spinning mills, dyeing, and weaving, further contributing to the proliferation of silk fabric production in Europe.

Italian city-states of Genoa

The Industrial Revolution – 1760 CE

During the Industrial Revolution, several technological advances made it much easier to produce and manufacture textiles in general. The most impactful innovation for silk production was the Jacquard Loom, which allowed for programmable patterns of weaving that were interoperable between looms. The Jacquard Loom enabled mass production of intricate design patterns for Silk and other fabrics.

Fun Fact: The “punch cards” that were used to “program” Jacquard Loom weaving patterns were actually precursors to the earliest computers, which used the same types of “punch cards” as the earliest computer programming languages.

The death knell of silk production in Europe came with the emergence of several silkworm diseases that wiped out the population in multiple countries. Europe’s industry never recovered, and by the 20th Century, China (and Japan) was again at the forefront of silk production globally.

Silk in Modern Day

Nowadays, silk fabric is produced all over the world. While China is still the largest silk producer, India, Brazil, and Vietnam are also major players in the industry. With the rise of alternatives such as cotton, nylon, and polyester, silk is once again a luxury good.

The silk industry is booming. Thanks to technological advances, silk production is more efficient than ever. As a result, despite its luxury status, the fabric is more affordable and accessible than at any point in the history of silk.

Properties and Characteristics of Silk Fabric

Due to the presence of protein and its unique production method, silk has many distinctive properties and characteristics.

For example, silk is the strongest natural fiber. It is also hypoallergenic and has low conductivity, making it ideal for winter clothes. The fabric’s softness and beautiful shine make it look luxurious.

As a solid fiber, you can stretch silk up to 20% without breaking. The strength of silk makes it ideal for clothing that needs to be lightweight but durable.

Unsurprisingly, silk is an excellent insulator. It keeps you warm in the winter and cools in the summer. Yet, it is still a breathable fabric, making it ideal for clothing that needs to be comfortable, like underwear and bedsheets.

Silk is a very absorbent fabric, taking up to 30% of its weight in moisture without feeling wet. The ability to absorb makes silk ideal for clothing that needs to be comfortable in hot and humid climates, such as sportswear.

Types of Silk Fabric

There are four types of natural silk produced around the world, they are: Mulberry silk, Eri silk, Tasar silk, and Muga silk. These varieties of silk are combined various ways, with different weaves, and sometimes blended with synthetic fibers, to create several types of silk fabrics. See information about these types of silk fabric below:

Charmeuse

Charmeuse is a lightweight and soft silk fabric that is woven with a satin weave. Charmeuse has a lustre on one side, and a dull finish on another. Charmeuse is shiner than satin, and is often confused for satin. Charmeuse is often used for scarves and lingerie.

Chiffon

Chiffon silk is very lightweight, with a texture similar to gauze, and made from twisted fibers. The fabric is slightly stretchy, and is very voluminous. Chiffon is often used in wedding dresses, scarves, and blouses.

Crêpe Silk

Crepe silk is a plain-weave silk fabric with a muted lustre and crimped texture.

Crepe silk comes in varieties that include crêpe-de-chine (“crepe of China”), Moroccan crêpe, and crêpe georgette.

Dupion Silk

A plain-weave, tightly woven double-thread silk with a crisp, textured appearance. Woven with different sized weft and warp threads produces a strong, durable fabric with a lustrous shine. Notice the occasional black speck which may run through the weave, this is part of the original cocoon of the silk worm.

A silk with plenty of charm and character, an iridescent look may be achieved by weaving two different coloured threads – known as shot silk. Dupion lends itself perfectly to elegant dresses, jackets, evening wear and bridal wear.

Georgette

Made with highly twisted yarns, Georgette is a sheer, lightweight , plain-weave fabric with a coarse texture. Not to be mistaken with Chiffon, Georgette is a heavier fabric though carries the same characteristics in terms of not creasing and holding a beautiful drape.

Dresses, blouses, evening gowns and scarves are a popular choice for putting Georgette silk to use.

Habotai

Soft and lightweight, Habotai is a plain-weave fabric with a smooth, glossy finish. Weights can range from 5mm to 8mm, and is the classic silk used for lining, but can also be used for making scarves, summer blouses or lingerie.

Organza

Sheer, fine and lightweight, Organza is an open-weave fabric with a smooth sheen. Although a thin material, its highly twisted threads create a strong, durable material.

Stiff and crisp, Organza is perfect for use on collars, veils, facings and evening wear.

Silk Satin

Oozing opulence, pure satin is a highly valuable material with a rich look and feel. The glossy, shiny surface is smooth to the touch and emits a mesmerising shine.

Silk satin doesn’t cling, unlike cheaper polyester versions which attract static electricity. Satin made from silk is far superior, and a popular choice of material for evening gowns and bridal wear to add a touch of luxury and glamour.

Shantung

Also known as Tussah silk. Made with short and coarse fibres, Shantung is stiff to the touch, whilst lightweight and airy. Similar to Dupion with its texture, though the finish tends to be more irregular.

A fabric that doesn’t crease and is great for use in shirts, dresses and trousers.

Silk crêpe-backed satin

With a satin face and a crêpe back, this is a reversible silk that can be used on both sides. A light-to-medium weight fabric which is incredibly smooth to the touch, with a lustrous shine.

Beautiful drapes can be created, and is often used for ball gowns, bridal wear and blouses.

Velvet

A luxurious, medium-to-heavy-weight silk fabric made with multiple warps and wefts. Unusually soft and creates a beautiful drape with a premium shine that catches the light in different ways.

How Is Silk Fabric Made?

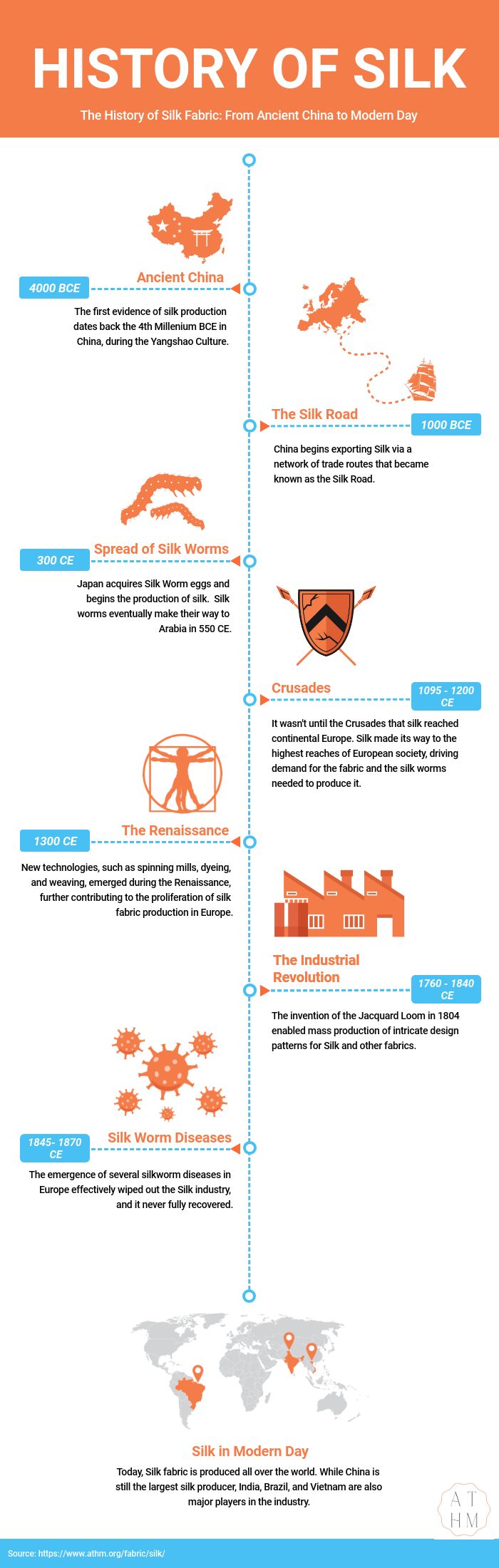

All silk production starts with silkworms. The process of raising silkworms is known as sericulture. It first developed in China in at least 4000 BCE, and continues today.

While there are many silkworm species, the most common is the Bombyx Mori. Silkworm farmers have bred Bombyx Mori for millennia specifically for silk cultivation. It is a flightless and helpless moth that cannot survive without the help of humans. Each Bombyx Mori lays 500 eggs in five days and then dies.

The biggest challenges for silk production begin after the silk worms lay their eggs. Farmers need to account for the temperature and keep the eggs at 65 degrees Celsius. Eventually, this temperature must be increased to 77 degrees Celsius. The slightest deviation from these temperatures could result in the death of the silkworms.

Silkworms hatch after ten days. They must be kept in a clean and well-ventilated area.

The farmers take careful account of the diet of their silkworms. They feed the silkworms a diet of mulberry leaves, and each worm can eat its weight in leaves every day. Over their short lives, silkworms increase in size by over 10,000x.

After gorging themselves on mulberry leaves for about a month, silkworms wrap themselves in a cocoon. It takes about nine days for a silkworm to make its cocoons.

Once the silkworms finish their cocoons, the farmers harvest the silk by dipping each cocoon in hot water. The hot water releases the silk thread spun by the silkworm.

Incredibly, each cocoon can produce up to 3000 feet of silk thread. Making a single silk yarn takes around six cocoons worth of thread. Companies can use silk yarn to produce garments and use it in other applications.

The dying process for silk is equally fascinating. Silk takes dye very well because of the protein structure of silk fibers. Additionally, silk thread is triangular instead of round. The distinctive shape of silk thread gives the fabric its distinctive sheen.

When silk is dyed, the color bonds with the silk fibers, and as a result, silk charmeuse will not fade as quickly as other materials.

The sericulture process is long and laborious. An estimated 40 million people are directly employed in the production of silk. Sericulture has played a role in countless communities, and many families in Asia have raised silkworms for generations.

How Is Silk Fabric Used?

Silk fabric has multiple applications. Companies often use silk in garments like shirts, skirts, and ties, and people also use it to make silk sheets and pillowcases. The fabric can also be used for upholstery, quilting, and blouses.

Designers prize silk for its beauty and elegance. It has a unique sheen that other fabrics do not have, while the color of silk makes it ideal for home decorating.

Applications Outside of Sewing Supplies

Silk is a robust fabric. Due to its strength, some companies have begun to use silk to produce items like parachutes and bulletproof vests. However, these products can be expensive due to the amount of silk required.

Some companies use silk charmeuse for multi-season clothing. Finally, other businesses market silk for people with sensitive body parts because its texture and softness are not harmful to the skin.

Advantages of Silk Fabric

There are many advantages to silk fabric. Silk is a solid and durable fabric that is also gorgeous and elegant. Additionally, silk is hypoallergenic and breathable, making it a good choice for clothing and bedding.

Disadvantages of Silk Fabric

Silk does have some drawbacks. It is a very delicate fabric and can be easily damaged. Moreover, silk charmeuse is a costly fabric.

Caring for silk can also be challenging. Silk must be hand washed in cool water with a mild detergent. You cannot bleach silk, and you cannot iron it as that could ruin the fabric. As a result, you must hang dry all silk dupioni fabric.

Alternatives to Silk Fabric

There are many alternatives to silk fabric, both natural and synthetic. Some natural silk alternatives include cotton, linen, and wool.

Since the 20th Century, many synthetic options have appeared on the market. These include polyester, nylon, and acrylic.

Each of these materials has its advantages and disadvantages. It is crucial to choose a fabric suitable for your needs and to consider other factors, such as cost, source, and sustainability.

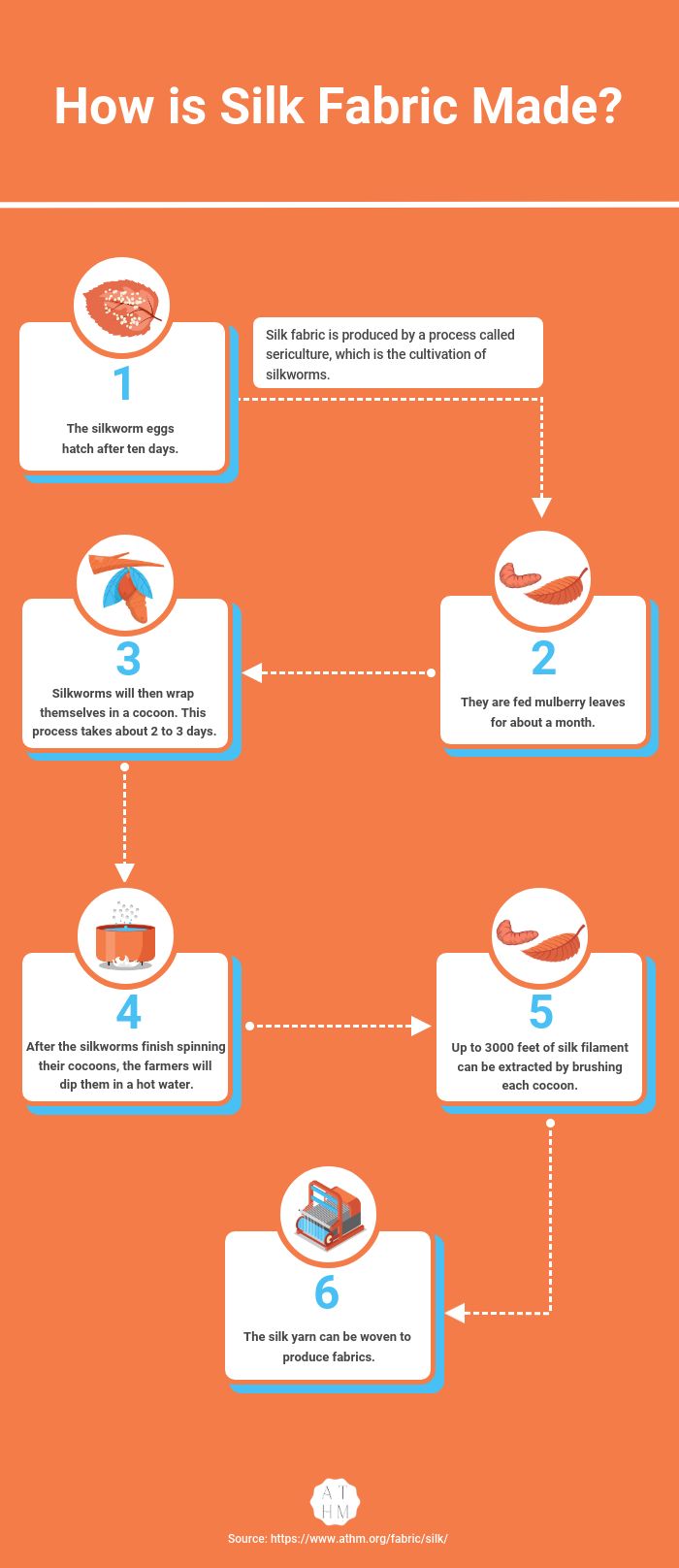

Where Is Silk Fabric Produced?

Asia produces the vast majority of silk, and China is the largest silk producer in the world, followed by India. Other silk-producing countries include Vietnam, Brazil, and Uzbekistan.

The silk industry is a big part of many economies in Asia. In China, the silk industry employs over two million people.

The silk industry has a long history in Asia. For centuries, Asian countries have been perfecting the art of silk production.

How Much Does Silk Fabric Cost?

A silk sheet can cost anywhere from $200 to $1,000, while a silk dress could run into the thousands.

The high cost of silk is due to the labor involved in producing it. Silkworms must be carefully monitored and fed a special diet. Farmers must harvest silkworm cocoons by hand, making the process long and labor-intensive. As a result, silk fabric is one of the most expensive fabrics on the market.

What Certifications Are Available for Silk Fabric?

There are many different types of certifications for silk fabric. Some focus on the treatment of the silkworms, while others focus on the production methods.

The Silk Mark

The Silk Mark is the most common certification for silk fabric. Silk with this certification will have been made in accordance with international silk production standards.

Organic Silk

The Global Organic Textile Standard (GOTS) is another common certification for silk fabric. This certification guarantees that the silk farmers use organic methods and that farmers don’t use harmful chemicals in the production process.

There is also the Organic Content Standard (OCS), which affirms that the silk contains a certain amount of organic materials.

Oeko-Tex

The Oeko-Tex Standard 100 is a certification given to silk tested for harmful substances and is safe for human use.

Sustainable Silk

Finally, the Forest Stewardship Council Certification (FSC) guarantees that farmers produce silk in a way that is environmentally friendly and sustainable.

What Is the Environmental Impact of Silk Fabric?

The silk industry has a significant environmental impact, the highest of any textile, natural or synthetic.

One of the most significant contributors is the extensive water and use central to silk production. Farmers typically harvest silkworm cocoons by boiling them, but the process involves vast amounts of water and energy.

Fresh water supplies are shrinking worldwide, but the production of one ton of silk requires 1,000 tons of water.

The energy required to boil the large amounts of water needed during sericulture often comes from coal-fired power plants, which are not environmentally friendly.

Since silkworms are sensitive to temperature and humidity changes, silk production facilities must use central heating and humidity control. This process uses a lot of energy, especially considering that most silk production is in Asia, with high temperatures and humidity levels.

Silk production also emits a lot of greenhouse gasses. In fact, silk production emits more greenhouse gasses than the production of any other textile.

The silk industry also dramatically impacts the environment because of the land needed to produce it. Farmers must feed silkworms a special diet of mulberry leaves. However, raising mulberry trees requires a lot of ground, leading to deforestation and habitat loss.

In addition, the silk industry relies on the use of pesticides and other harmful chemicals. To protect the silkworms, many farmers employ chemicals like formaldehyde and chlorine to sterilize the areas around their fans. These chemicals can pollute the air and water and harm local wildlife.

Even after the production process is finished, caring for silk has a much higher environmental impact than other fabric types. For instance, dry cleaning silk is more energy intensive than traditional washing methods.

Still, one of the benefits of silk is that it is a zero-waste fabric. In particular, farmers use all of the silkworm cocoons to produce silk fabric. The byproducts of production are recycled or reused. After farmers harvest the mulberry leaves, they eat the fruit from the trees and use the wood for timber or fuel.

The wastewater from boiling the cocoons absorbs beneficial additives from the silk, and many industries use the wastewater from silk manufacturing in numerous products.

Finally, since silk is an organic fabric, it is not a pollutant. When you discard silk, it will biodegrade. The fact that silk biodegrades is one of its most significant advantages over synthetic alternatives like polyester.

Moreover, there are ethical concerns behind the production of silk. The silk industry relies heavily on child labor. In some silk-producing countries, children as young as five years old work on silk farms.

These children often work long hours in harsh conditions. Working on a silk farm can expose child laborers to harmful chemicals and pesticides and risk them being injured by silkworms or machinery.

There are also ethical concerns behind using silkworms to produce the silk thread needed for silk fabric.

Overall, silk has a tremendous environmental impact despite the advantages the fabric offers. With that in mind, you might want to consider alternatives if you are looking for a more comprehensively sustainable option.

Conclusion

Silk is a beautiful and unique fabric with many benefits and a long, rich history. It is robust, hypoallergenic, and breathable. Silk fabric also has a luxurious feel and look. Despite its lengthy use, silk is still considered high fashion and a luxury item. The fabric is often blended with other materials, both natural and synthetic, to produce distinctive blends suitable for a variety of uses.

However, silk has historically been a costly fabric, though it is becoming more affordable and accessible. Silk has a significant environmental impact and has played a negative role in labor practices in some countries. Given that, it’s crucial to weigh the pros and cons before choosing silk for your next project.