Polyester fabric is one of the most commonly used fabrics in the world. Its invention completely changed the world and continues to impact the daily lives of millions in industry, fashion, and the lives of millions.

This versatile fabric hails from the experiments of British scientists, who manufactured the wrinkle-resistant material. Today, this fabric appears in various items, such as clothing, upholstery, and tires.

This article covers everything you would want to know about polyester fabric. By the end of this article, you will be a polyester expert.

What Is Polyester?

Polyester fabric is a synthetic fabric made from polymer. Polyester was first invented in 1941 by British scientists. The scientists made the first polyester fabric from coal, water, and air.

It is an artificial fabric, meaning it does not occur naturally. Modern industry produces polyester from petroleum products, and you make polyester from long chains of synthetic polymers.

You can make these polymers from small molecules called monomers. Polyester is a type of plastic that can be molded or shaped into any form.

Companies use polyester to make things like:

- Clothing

- Furniture upholstery

- Carpeting

- Tires

- Insulation

Polyester has incredible durability, so companies use it in products that need to withstand a lot of wear and tear. Polyester is also wrinkle-resistant and easy to care for, which is why it is a popular fabric for clothing.

Polyester fabric is also very lightweight, which makes it ideal for summer clothing. It is also an excellent choice for activewear because it dries quickly and does not absorb sweat. It is also lightweight, so it is comfortable to wear while exercising.

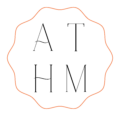

History of Polyester

To understand the history of polyester fabric, you must take a step back to the creation of polyester plastic.

The first research into polyester plastic began in 1926. The chemical company DuPont started researching massive molecules due to the possibility of creating synthetic fibers.

Scientists at DuPont discovered nylon plastic in the last 1930s. Nylon was one of the first synthetic fibers produced, which was a step towards the invention of polyester. There were many scientists involved in the development and discovery of nylon. However, many consider W.H. Caruthers the inventor of nylon plastic.

The Invention of Polyester

Several British scientists built upon Caruthers’ work and created the first polyester fabric during the peak of the Second World War. This revolutionary fabric was initially named Terylene.

DuPont purchased the rights to Terylene in 1946 and built upon the British research of the Second World War. Later that year, DuPont developed another type of polyester fiber called Dacron.

Dacron was not the last polyester fiber to get invented. In 1958, Eastman Chemical developed another thread called Kodel.

Terylene, Dacron, and Kodel are all referred to as polyester fabric. Your polyester clothing is likely one or a combination of the three materials.

Du Pont later changed the name of Terylene to Polyester and introduced it in the United States. Polyester fabric quickly became popular because it was hardy. Polyester fabric was also easy to care for and wrinkle-resistant. Polyester quickly became the fabric of choice for many clothing manufacturers.

Polyester fabric was trendy in the 1950s and 1960s. Companies began using polyester to produce shirts, dresses, and suits, and other companies started making curtains, bedding, and carpeting using polyester.

Polyester became less prevalent in the 1970s and 1980s because it was associated with poor quality and tacky clothing. Polyester became popular again in the 1990s due to its wrinkle-resistant properties.

Modern Polyester

Many people don’t know that modern polyester has not changed much since its invention in the 1940s. The lack of change confuses many people because the clothing of the 60s and 70s feels different than modern polyester blends.

The change is due to how the polyester fabric is knit. Older clothing was often double knit, and as a result, the material was much more significant.

As consumer preferences and demands changed, companies began using smaller fibers and single-knit technology. Additionally, companies developed new technologies that have made modern polyester comfortable, fashionable, and strong.

Polyester Innovations

Some of the other inventions and developments that impacted modern polyester include:

The resin that binds polyester has dramatically improved in the last 50 years. The higher quality resin creates smaller seams which irritate sensitive skin less. Resin is one of the most valuable developments, and this technology is a closely guarded trade secret.

Companies began adding different polyester additives that changed the fabric’s color and appearance. The additives made polyester retain its color, hang more naturally, and make it less shiny.

The development of microfiber was a game changer. Microfibers are much smaller than traditional polyester fabric fibers (about 1/100 the size of a human hair). Microfibers make modern clothing of this fabric more comfortable.

The ability to crimp, stretch, and change the shape of polyester fibers also significantly impacted the popularity, feel, and quality of the clothing.

Polyester is now one of the most popular fabrics in the world. Companies use polyester to make clothing, furniture, carpets, tires, and insulation.

Characteristics of Polyester Fabric

Polyester fabric has many characteristics and properties that make it useful in the modern world. Polyester is wrinkle-resistant, easy to care for, and often blended with other fibers to create a more durable material.

- Fabric Breathability: Polyester is a breathable fabric and often gets blended with cotton or other materials to improve its breathability. Polyester and cotton blends are some of the most popular in the world and combinates the comfort of cotton with the quick drying nature of polyester.

- Moisture-Wicking Abilities: Polyester is one of the best fabrics you can find if you require a moisture-wicking material. This synthetic material moves moisture away from the body, keeping you dry. It’s also breathable, lightweight, and shows durability. You’ll find that outdoor clothing typically contains polyester for this reason.

- Heat Retention Abilities: Unfortunately, since you make polyester with petroleum, it means that polyester is flammable, and the fabric will melt if it comes into contact with a flame. As a result, drying polyester fabrics at high temperatures can permanently damage the fabric.

- Stretchiness: Since polyester fibers are artificial, they contain no elasticity. So, 100% polyester yarns will usually not have any stretchiness. However, textile experts have discovered that new weaving methods can incorporate a bit of stretch into the fabric, and you’ll find that polyester blends usually have some stretch characteristics.

- Pilling/Bubbling: Polyester is susceptible to pilling, which is when small balls of fabric form on the fabric’s surface. Pilling happens when materials rub against each other and when you wash a garment. Once pilling begins on a polyester fabric, the damage is permanent.

Types of Polyester

There are two types of polyester:

- Polyethylene Terephthalate (PET or PETE)

- Polybutylene Terephthalate (PBT)

PBT is a type of polyester that you make from Polybutylene Terephthalate. PBT is a less common polyester type, but it is sometimes used instead of PET because it has a higher melting point.

In addition to PET and PBT, polyester comes in several different forms. The four most common forms of polyester are filament, tow, staple, and fiberfill.

A polyester filament is a single long strand most frequently used to produce clothing. Polyester staples are shorter pieces of filament cut at predetermined lengths. Industry leaders commonly use polyester staples when blending polyester with other fabrics.

Multiple filaments comprise a tow of polyester. The filaments are close together but still leave space for additional fabric.

Finally, fiberfill is a type of polyester that has the most volume. It helps produce insulation, pillows, and cold-weather clothing. It can take the place of materials like goose down.

The fluffiness of fiberfill makes it an excellent insulator. Of the four types of polyester, filament and staple are the two most common types.

How Is Polyester Made?

There are several methods for producing polyester. The polyester production process you use depends on the desired final form of the polyester. Basic steps for producing polyester fabric include:

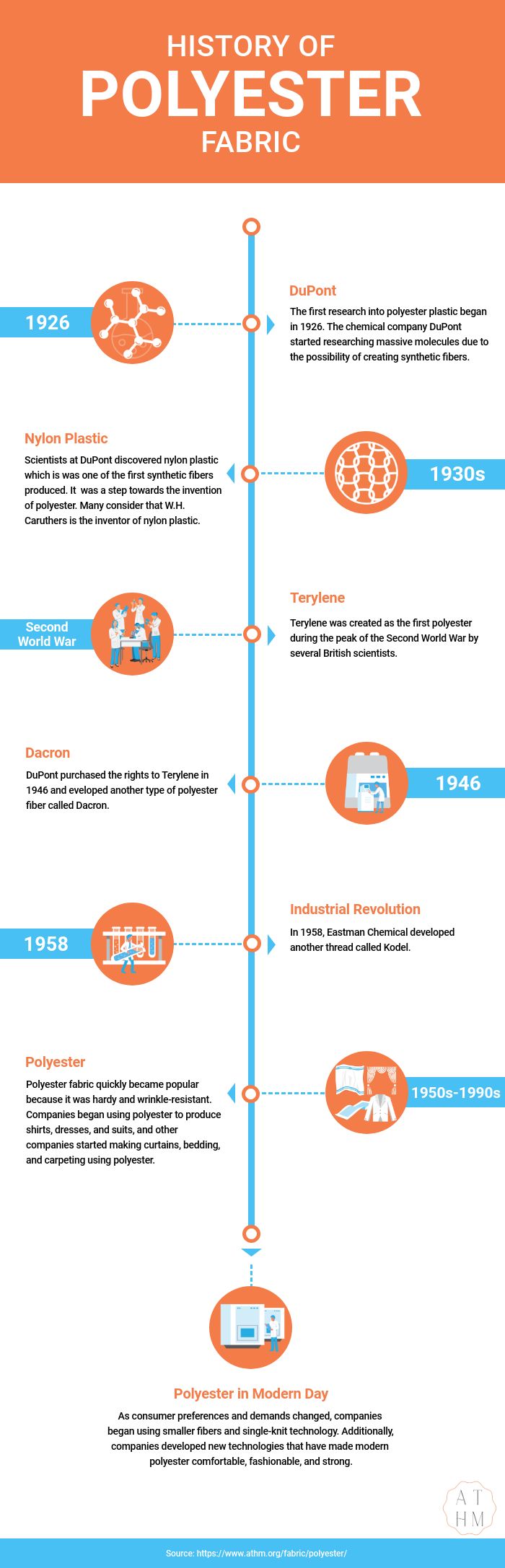

Step 1

You make polyester from petroleum, coal, and water. The first step in making polyester is to create what is called polyethylene terephthalate, or PET.

Manufacturers produce PET by combining ethylene glycol and terephthalic acid. These two substances are mixed and then heated until they form a clear liquid, and that liquid is then cooled and made into pellets.

Step 2

The pellets then get melted and spun into fibers. Companies turn the threads into the fabric that we know as polyester. Polyester is made by extruding molten polyester resin through tiny holes, which cools and solidifies the resin into long strands of fiber. Once in fiber form, manufacturers can turn polyester into fabric in various methods.

Step 3

Some of what makes polyester such a popular fabric is its flexibility. Companies can turn polyester into various materials, including satin, chiffon, and velvet. Polyester is also often used to make blended fabrics, like cotton or wool.

The yarns used in the warp (lengthwise) direction are called the fill yarns, and the yarns used in the weft (crosswise) direction is called the ground yarns. Polyester is often used as the ground yarn in fabric because it is robust and does not stretch.

Companies creating polyester can also use it to make non-woven fabrics. These fabrics get produced by bonding polyester fibers with heat, chemicals, or adhesive. Polyester, non-woven fabrics are often used in filters and products like diapers and upholstery padding.

Another common form of polyester is fiberfill. Manufacturers commonly use this polyester to produce insulation, jackets, and blankets. Polyester fiberfill is made by taking polyester pellets and melting them.

The molten polyester then gets extruded through a die with small holes. As the polyester cools, it forms into long strands of fiber. Those fibers are then cut into the desired length. Different products require different sizes of thread.

How Is Polyester Used?

Polyester is a versatile fabric that has many uses. Industry often blends it with other materials, like cotton or wool. By combining polyester with another fabric, the company can get the beneficial characteristics of both fabrics.

The most common application of polyester is clothing, as it is wrinkle-resistant and easy to care for. You can also use polyester in linings, curtains, upholstery, and carpets.

Industrial applications for polyester include tire cords, hoses, berry boxes, and bottles. Many consumer goods like cell phone cases, blankets, and sleeping bags also use polyester.

Advantages of Polyester

The advantages of polyester have many benefits, making it a popular choice for fabric. It is wrinkle-resistant and has a high resistance to tearing. Polyester is also easy to care for, as it can be washed in the machine and does not require ironing. Polyester is also a budget-friendly fabric option.

Polyester is often used in sportswear and activewear because it is lightweight and breathable. The fabric is also a popular choice for making blankets and bedding sheets, as it is warm and cozy.

Another advantage of polyester is that it is static-resistant. Companies use polyester to make clothing for people who work in environments prone to static electricity, such as laboratories and cleanrooms.

Disadvantages of Polyester

There are several disadvantages of polyester as well. Polyester is not as absorbent as natural fibers, so it can feel sweaty and uncomfortable to wear in hot weather. Polyester is also not a good choice for people with allergies, as it can cause skin irritation.

One of the most significant disadvantages of polyester is that it is not biodegradable, so it can cause environmental pollution. It is not biodegradable because you make it out of petroleum.

Alternatives to Polyester

There are many different alternatives to polyester. There are alternative natural and synthetic fabrics.

Other Synthetic Materials

Polypropylene is another synthetic fiber often used as an alternative to polyester. Polypropylene is more breathable than polyester and does not hold sweat or odor as much as polyester.

Polypropylene is also more absorbent than polyester, making it a good choice for activewear. Polypropylene is also biodegradable, so it is a more sustainable choice than polyester.

Natural Fabrics

Cotton is the most popular natural fiber with several characteristics that make it more appealing than polyester. Cotton is more absorbent than polyester and is a good choice for hot weather.

Cotton is also a good choice for people with allergies and is less likely to irritate your skin. However, cotton is less durable than polyester and is more likely to wrinkle.

Linen is also one of the natural fabrics often used as an alternative to polyester. Linen is absorbent and breathable.

Linen is also more durable than cotton and is less likely to wrinkle. However, linen is more expensive than polyester and cotton.

Hemp is a sustainable natural fiber often used as an alternative to polyester. Hemp is absorbent, breathable, and durable.

Hemp is also less likely to wrinkle than cotton and linen. However, hemp is more expensive than polyester and cotton. Hemp is one of the most appealing alternatives to polyester because it has many beneficial characteristics.

Unfortunately, governments used to limit commercial hemp production because of its association with marijuana.

Wool is a natural fiber often used as an alternative to polyester. Wool is absorbent and breathable, making it a good choice for hot weather.

Wool is also more durable than cotton and linen. However, wool is more expensive than polyester and cotton.

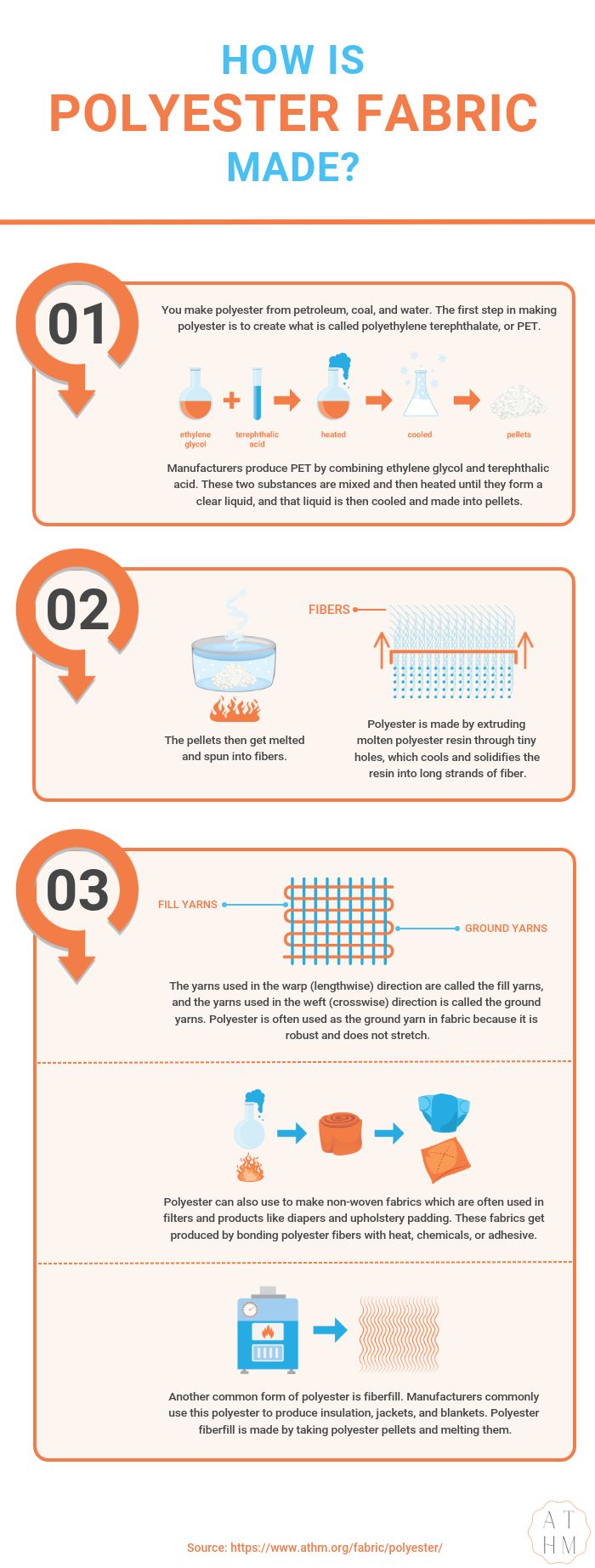

Where Is Polyester Produced?

Companies produce polyester all over the world. However, the largest producers of polyester are in Asia. China is the largest producer, but other major polyester producers include India, Indonesia, and Bangladesh.

Companies in Europe and North America also produce polyester. However, production outside of Asia is limited.

How Much Does Polyester Cost?

Polyester is a budget-friendly fabric option. Polyester is often less expensive than natural fibers like cotton and linen. It is also less costly to produce and purchase than wool and alternative synthetic fabrics like polypropylene. Typically, you can expect to pay between $5-$10 per yard of polyester.

What Certifications Are Available for Polyester?

Polyester is available in several different certifications. Polyester can be certified as recycled, organic, or fairtrade.

Recycled Polyester

Companies make polyester from post-consumer or post-industrial waste. Polyester can be certified as recycled if it contains at least 50% recycled content.

Organic Polyester

You can make organic polyester from renewable plants like bamboo, soy, or corn. Polyester can be certified as organic if it contains at least 95% organic content.

Fairtrade Polyester

On the other hand, industries produce Fairtrade polyester in factories that meet fair labor standards. Polyester can get certified as Fairtrade if the factory is certified by Fairtrade USA or the Global Organic Textile Standard. Polyester can also be certified as sustainable if it meets specific environmental standards.

What Is the Environmental Impact of Polyester?

Polyester has both a positive and negative impact on the environment. However, the negative implications easily outweigh the positive ones.

Since polyester is affordable, easy to produce, and has many uses, it is one of the most popular fabrics in the world. Unfortunately, its popularity is a double-edged sword. Polyester has a significant impact on the environment. both positive and negative.

Positive Environmental Impact of Polyester Fibers

One of the best features of polyester is the fact that it is winkle-free. As a result, polyester clothing does not need to be ironed or pressed. It is also quick drying, so it can quickly be hand washed and worn again.

These characteristics have a positive impact on the environment. By skipping ironing and pressing, the user can reduce their energy consumption. Additionally, since it is a durable material, it can be used repeatedly, decreasing the need for new materials.

Decreasing the need for additional fabrics is particularly important due to the high water usage of many fabric types during production. Additionally, polyester requires much less water to produce than other types of fabrics.

One of the other benefits of polyester is that it is recyclable. Polyester can be melted down and made into new polyester fiber. Companies can use recycled fiber to create unique clothing, carpet, or other types of clothing.

The technology needed to recycle polyester is relatively new and still quite expensive. As a result, few companies utilize it, and the high price of recycled polyester often scares consumers.

Unfortunately, only a tiny amount of the world’s polyester is recycled yearly, most of which is in the trash.

Polyester and Oil

Despite these positive benefits, polyester has a much more significant negative impact than a positive impact on the environment. You produce polyester from petroleum, which is a non-renewable resource. Additionally, the production of polyester is an energy-intensive process.

The production of polyester uses over 70 million oil barrels each year. Extracting and refining oil has a measurable negative impact on the environment.

Greenhouse Gases and VOCs

The production of polyester also emits greenhouse gases and pollutes water. Polyester factories release volatile organic compounds (VOCs) into the air. These VOCs contribute to smog and can cause respiratory problems.

Additionally, the production of polyesters releases harmful chemicals that are known carcinogens. These chemicals are often captured in the water supply and consumed by humans.

The Impact of Polyester Production and Wildlife

Polluted water also has a tremendous impact on wildlife. Polyester production creates a great deal of wastewater. This wastewater often gets dumped into waterways, polluting the water, harming the local ecosystem, and spreading to the ocean.

The release of carcinogens is particularly concerning because the countries that produce most of the world’s polyester (China, Indonesia, and Bangladesh) have few environmental regulations.

One of the other significant issues with polyester is that it is not biodegradable, so it can take hundreds of years to break down in landfill.

Polyester and Microplastic Pollution

Polyester is also a significant contributor to microplastic pollution. Polyester contributes to microplastic pollution before it becomes trash. Every time you wash the polyester fabric, it releases many microplastics.

In summary, polyester has one of the most significant impacts on the environment of any type of fabric. The benefits of polyester outweigh its considerable negative impact on the environment.

Minimizing the Environmental Effects of Polyester Garments

If you are planning on purchasing new clothing made from polyester, try buying items made with recycled polyester or plastic.

Additionally, try to avoid washing this type of clothing as much as possible. Since it is quick to dry, you can hang your clothes outside and let them air out instead of washing them.

Finally, if you need to throw away your clothes, identify a recycling location that will adequately dispose of the plastic. If you follow these practices, you can minimize the impact your clothing may have on the environment.