Nylon is a synthetic fabric that was first developed in the 1930s. It is made from a polymer of nylon, which is a synthetic material. Nylon is strong and durable, making it a popular choice for clothing, upholstery, and other items.

It can repel water and is lightweight, strong, durable, heat-and-cold-resistant, mildew-resistant, and abrasion-resistant – giving it an almost infinite number of uses in commercial products.

On the negative side, it is a chemical pollutant that is harsh on the environment and requires fossil fuels for production.

While the production of nylon fabrics began in the United States in the 1930s for use in women’s clothing, we currently use it in thousands of everyday items and applications. The clothing, automotive, and electronics industries incorporate nylon fibers into many of their products. Countries all over the world produce and use nylon products.

Common nylon products include clothing, ropes and fasteners, food packaging, hair combs, sleeping bags, pipes, tires, surgical thread, toothbrushes, cookware, machine parts, parachutes, umbrellas, furniture, carpeting, and luggage.

However, there are thousands of other uses. It is one of the most common synthetic materials in the world and is likely to remain so for the foreseeable future.

What is Nylon Fabric?

Nylon fabric as a strong, tough, elastic, synthetic polyamide material.

Manufacturers produce nylon through an energy-intensive chemical polymerization process that uses petroleum and releases many chemicals into the environment.

Nylon does not have other common names or well-known brand names. It is so ingrained in our lives and culture that we’ve identified it by the same name since 1931.

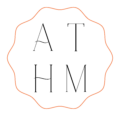

History of Nylon Fabric

Harvard University researcher Wallace Carothers invented nylon – the first synthetic fiber – in 1935. Carothers was an organic chemistry lecturer at Harvard before his research in nylon.

In the 1930s, the DuPont de Nemours, Inc. company – an American leader in materials science, chemicals, and manufacturing – wanted to invest in scientific innovation and find a more durable substitute for rayon.

Charles M.A. Stine, the head of the DuPont Chemical Division, recruited chemists and researchers for this scientific expansion. Carothers joined Dupont in 1928 and focused his research on synthetic substances for industrial use.

Carothers was one of the early pioneers of polymerization. A polymer is a long chain of molecules consisting of smaller monomers – molecules that can bond with other identical molecules.

Within a few years, Carothers and the DuPont Chemical researchers used various polymers to create neoprene and the first polyester version.

In 1931 Carothers and his team created a new polymer that became the earliest version of nylon. Using chemicals found in petroleum, they created polymers from smaller molecules.

They called the early version “Nylon 66,” a reference to its chemical structure of six carbon atoms per molecule. The nylon had long, stretchy fibers that were durable.

DuPont successfully applied for a nylon patent in 1935. A few years later, it constructed a nylon manufacturing facility in Seaford, Delaware, that could produce twelve million pounds of nylon a year. The nylon revolution had begun.

Sadly, Carothers committed suicide in 1937 and did not see the global phenomenon nylon became.

DuPont introduced nylon at the New York World Fair in 1938. The following year they began selling a limited supply of nylon, and in 1940 they released it to the general public. Nylon became an immediate success.

DuPont originally focused on using nylon fabrics in women’s hosiery. Women’s stockings previously had silk and rayon. Nylon stockings were a potential upgrade.

DuPont marketed nylon as a more durable and superior material than silk and rayon. Nylon’s original name – Nuron – was the words “no run” spelled backward. The reference was that the nylon material would not tear like silk stockings and its less durable predecessors.

Nylon hosiery sold out in stores across the country. DuPont produced millions of pounds of nylon and captured almost a third of the hosiery market.

However, DuPont soon shifted production away from nylon fabrics in women’s hosiery and consumer products to military manufacturing. By 1941 the U.S. was embroiled in World War II and needed the nation’s factories to aid in the war effort.

DuPont began manufacturing synthetic nylon fabrics for military infrastructure to aid in national defense. Instead of women’s hosiery, nylon was for aircraft fuel tanks, vehicle tires, parachutes, flak jackets, shoelaces, mosquito netting, and hammocks. Nylon was “the fiber that won the war.”

Post-War Production

After the war ended, DuPont resumed manufacturing nylon stockings for women. Stores began selling nylons to incredible demand.

Crowds of hundreds and sometimes thousands arrived at stores to buy nylons, and the product quickly sold out. Newspapers called these frenzied crowds the “Nylon Riots.” In one case, 40,000 people showed up in Pittsburgh to buy a limited supply of nylons.

As nylon production gradually ramped up, demand fell. Throughout the 1960s and 1970s, the popularity of nylon finally started to wane.

People still purchase nylon products today, but they certainly are not lining up at stores and rioting to capture a limited supply of women’s hosiery. The global production of nylon in 2020 was 8.9 million tons.

DuPont continued manufacturing nylon for the next several decades. However, they recently announced a plan to divest plastics and focus on more high-margin items like electronic products and electric vehicles.

Most apparel today does not contain pure nylon. Instead, manufacturers use nylon blends or a polyester blend with cotton and spandex. However, nylon usage extends beyond apparel. It is a part of thousands of commercially-manufactured items.

Properties and Characteristics

All nylon is strong yet lightweight material. It is durable, stretchy, heat-and-cold-resistant, abrasion-resistant, and shock-absorbing. Most nylons have moisture-wicking and water-resistant properties. Nylon is easy to wash and dye, and it cannot catch fire.

Additional Nylon Properties

- Nylon fibers are smooth and soft

- Durable

- High tensile strength

- High impact resistance

- Water-resistant

- Mildew-resistant

- Flexible

Disadvantages

Nylon has several undesirable properties.

- It does not hold up well to sunlight exposure

- Not very static resistant.

- Expensive to manufacture

- Requires a lot of resources

- Uses fossil fuels

- Pollutes the environment

- Not biodegradable

Types of Nylon Fabric

Nylon is a synthetic polymer derived from petroleum and crude oil. It has adipic acid and hexamethylene diamine acid, each with six carbon atoms per molecule. It has one hundred or more repeating chains of carbon, oxygen, and hydrogen atoms. A single filament might have millions of molecules. Its structure makes it stronger than other fibers.

There are eight types of nylon and five main types: Nylon 6, Nylon 4,6, Nylon 510, Nylon 1,6, and Nylon 66. Each of the nylon resins has specific properties that make it suitable for some things but not others.

66

66 is the original version that Carothers discovered. Nylon 66 is heat, oil, and chemical resistant. Engineers use it in wear pads, guide wheels, and slide bearings. However, it is not as effective in dry environments, and the molding process is difficult.

510

The 510 version is very strong and durable but is expensive to make. We generally use it for industrial applications and scientific purposes.

6

Nylon 6 is more flexible than its counterparts, which makes it a good choice for ropes and circuit breakers. It also has a shinier finish which makes it popular for car parts like grills or stadium seats.

1,6

The 1,6 version has a high moisture absorbance and is not a good choice for fabric.

4,6

This version has a high operating temperature and works well in engine components like transmissions, brakes, and cooling systems. It also has good chemical resistance.

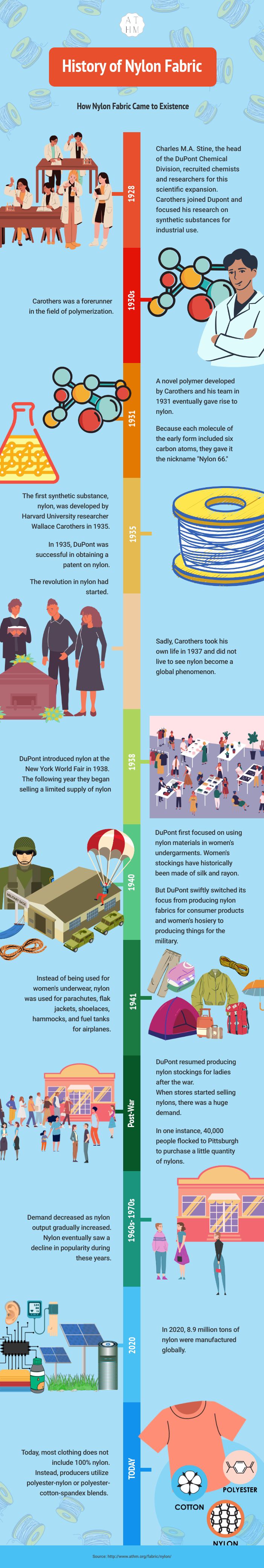

How Is Nylon Fabric Made?

Nylon creation is through a chemical reaction called polymerization. A polymer is a long chain of molecules consisting of smaller monomers – molecules that can bond with other identical molecules. In polymerization, those monomers form a long chain by a chemical reaction.

There are two types of polymerization: Chain Reaction (Addition), Polymerization Step-Reaction (Condensation) Polymerization. Nylon creation is through condensation polymerization.

In condensation polymerization, water is a typical byproduct.

Some of Carothers’ early struggles related to condensation and the water byproduct. In his early research, water from the condensation polymerization reaction was dripping back into the mixture and preventing more polymers from forming. Once Carothers realized this, he adjusted the equipment to account for the water and removed it from the process.

Condensation Polymerization often has two different molecular components that combine in an alternating structure. In nylon, those molecular components are amine, hexamethylene diamine, and adipic acid (Carothers and DuPont named the first nylon Nylon 66 because the adipic acid/ dicarboxylic acid and hexamethylene diamine each had six carbon atoms).

Condensation Polymers form slowly and require heat. They usually have a lower molecular weight than Addition Polymers. Additionally, the process by which the polymer forms gives it increased crystallinity and tensile strength.

Once the nylon condensation polymer fibers are formed, and the water evaporates, the resulting product is a crystalized nylon salt. The chemist converts the nylon salt from a solid to a molten substance or viscous state by applying heat. The chemist then forces the fluid polymer through a spinneret device.

A spinneret is a type of die that manufacturers use for fiber. It’s usually a metal plate with between fifty and a hundred round, small holes. The process of forcing the nylon (or any viscous polymer) through the holes of the spinneret is called spinning. The product that comes out of the spinneret is called a filament.

Nylon filaments are still hot when emerging from the spinneret. The filaments are all uniform because they emerge through identical-sized holes in the spinneret. At this point, the manufacturer can stretch them and create any length, shape, or pattern.

The final step in the manufacturing process is cooling the nylon filaments. Usually, the manufacturers will use machines to blow cool air over the filaments. This step returns the nylon filaments to their solid state.

How Is Nylon Fabric Used?

Nylon’s unique properties make it a popular choice for apparel, ropes and fasteners, machine parts, and cookware – among many other things.

We might not realize that we use nylon every day in products around our homes, workplaces, and our vehicles. Here are some common uses of nylon.

Nylon in Apparel

Nylon has several properties that make it a good choice for apparel fabric: it retains its form well after cleaning, is durable, is resilient to stretching, retains color, dries quickly, and resists dirt, sweat, and moisture. It is also resistant to occasional UV exposure and chemicals.

Clothes that have nylon fabrics include the following: hosiery, swimwear, jackets, athletic gear, socks, and underwear.

We rarely use pure nylon fabrics in clothes, however. Most apparel with nylon contains a nylon blend with cotton, polyester, and spandex.

Nylon in Fasteners

Nylon’s strength, minimal weight, and resistance to heat and cold make it an effective choice for fasteners. Ropes using a woven pattern often are made of nylon. For example, we use nylon ropes for boat docking and towing.

Nylon ropes are stronger than natural fiber ropes and any other type of synthetic rope. They do not rot, they are elastic, and they absorb extreme shock without breaking. These properties make nylon one of the most reliable materials.

Nylon bolts, nuts, screws, spacers, and pins are also popular fastener items.

Nylon in Machine Parts

Nylon is a popular choice in machine parts because of its low cost and heat resistance. For example, the electronic industry often uses nylon in circuit board hardware because it is prone to heat with usage. Many electrical devices use nylon fasteners because they also have good electrical resistance.

Nylon is also a good choice in machines that rotate or slide because it will not heat with friction. Manufacturers can inject mold or machine nylon into precise parts. They use nylon in bearings, wear pads, washers, bushings, sprockets, and tubes, among other things.

Nylon in the Automotive Industry

Nylon is the most popular synthetic material in the automotive industry. Automakers prefer it for its durability, heat resistance, and chemical resistance. Because nylon is lightweight, it can replace metal and steel components in cars and improve fuel efficiency.

Automakers often use nylon in the vehicle engine because it holds up against high temperatures and chemical lubricants like oils and synthetic oils. Nylon’s heat-resistant properties also work well in vehicle airbags.

Unlike steel, nylon is also resistant to corrosion which extends the lifespan of a vehicle.

Nylon in Cookware

Nylon is a popular choice in cookware because of its heat resistance, durability, and texture. It is gentle on non-stick surfaces. Many cookware companies dye nylon in various colors to make it more appealing for kitchen decor.

Nylon cookware has a comfortable grip and is machine-washable for ease of use. Examples of nylon cookware include spatulas, slotted spoons, tongs, turners, and forks.

Other Nylon Uses

Nylon is also a common material in umbrellas, luggage, bridal veils, netting, fishing lines, dental floss, seatbelts, and tire cords. All nylon is strong yet lightweight material. It is durable, stretchy, heat-and-cold-resistant, and shock-absorbing. It does not absorb much water. It is easy to wash and dye. It cannot catch fire.

Advantages of Nylon Fabric

Nylon filaments are smooth and soft. They have high tensile strength, high impact resistance, and high chemical resistance. The material is strong, durable, lightweight, and moisture-wicking.

Disadvantages of Nylon Fabric

However, nylon does have a few undesirable properties. It does not hold up well to sunlight exposure, and it is not very static resistant. It is expensive to manufacture and requires a lot of resources.

Additionally, nylon has a severely detrimental impact on the environment.

It has the following disadvantages:

- Does not hold up well to sunlight exposure

- Not very static resistant.

- Expensive to manufacture

- Requires a lot of resources

- Uses fossil fuels

- Pollutes the environment

- Not biodegradable

Alternatives to Nylon Fabric

Despite the remarkable strength and versatility of nylon textiles, it is not a sustainable fabric. Because of the expense of producing it and its significant environmental impact – environmental organizations and governments are seeking alternative textiles.

Bio-Nylon

Bio-Nylon is a type of nylon alternative made from renewable resources. Instead of petroleum and crude oil, researchers use the bioconversion of sugar to create nylon. Its creators estimate an 85 percent reduction in greenhouse gas emissions. An example is RENNLON.

Popular apparel brands like LuluLemon have pledged to start using bio-nylon in their products to reduce the environmental impact.

Recycled Nylon

Recycled nylon is a type of one hundred percent recycled nylon. Recycled nylon material is similar to brand new nylon, and the manufacturer can recycle, recreate, and remold it into different products. They use it in apparel, automotive parts, and interior design. An example is ECONYL.

Lyocell

Lyocell are semi-synthetic fabrics that is more eco-friendly than nylon. Manufacturers use wood from eucalyptus trees to create Lyocell. They grind the wood chips into a pulp of raw cellulose and then force it through a spinneret.

Lyocell is a soft material that works well in apparel. It is more absorbent than cotton textiles.

Lyocell production does not use any toxic chemicals or require a lot of water or other resources. Eucalyptus trees are easy to replenish, so many consider Lyocell a sustainable type of fabric.

Tencel is a company that sells Lyocell products.

Polyester

Polyester is another of the synthetic fibers that manufacturers make through the condensation polymerization chemical reaction.

Like Nylon, it is a melt-spun fiber and one of the synthetic polymers. It also uses fossil fuels for production. Polyester has a negative environmental impact because it is not biodegradable or sustainable. It also is not as durable as nylon.

It is cheaper to produce polyester than nylon textiles. It also works better in most clothing because it has moisture-wicking properties and is breathable. Like nylon, it is machine-washable, water-resistant, and doesn’t require significant care. It also is a popular material in bed sheets, linens, dresses, and suits.

Cotton, Linen, Hemp, Bamboo, and Wool

Cotton, linen, hemp, and wool have been around for centuries and are four of the most sustainable nylon alternatives. They are naturally occurring and renewable resources with less environmental impact than nylon.

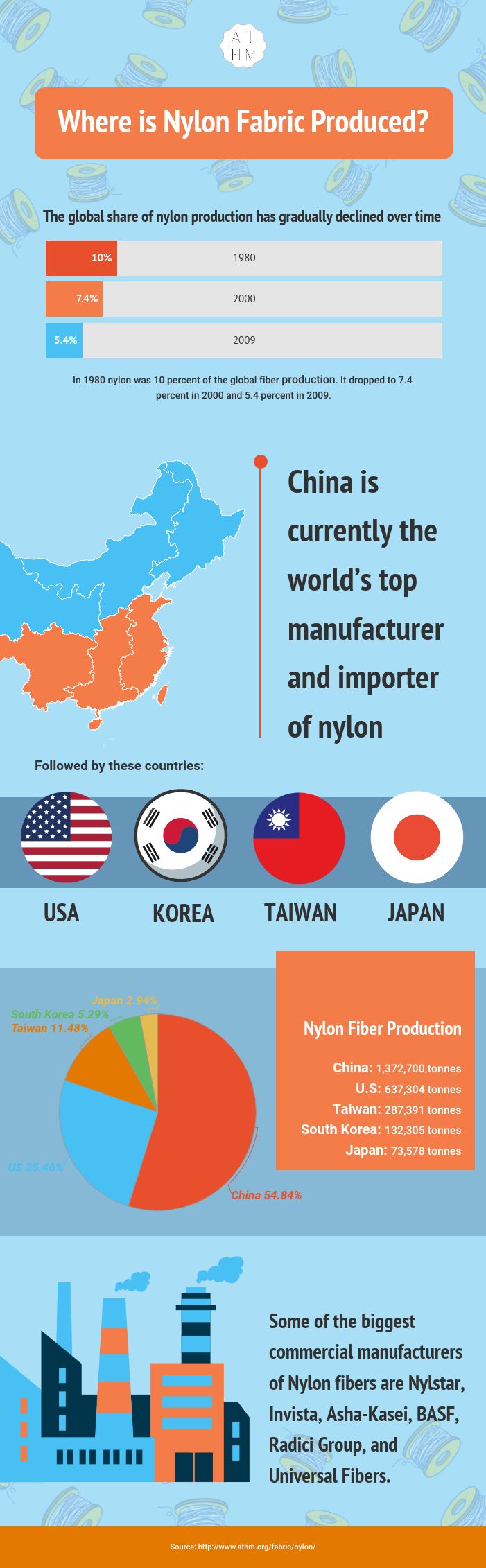

Where Is Nylon Fabric Produced?

The global share of nylon production has gradually declined over time. In 1980 nylon was 10 percent of the global fiber production. It dropped to 7.4 percent in 2000 and 5.4 percent in 2009.

China is currently the world’s top manufacturer and importer of nylon, followed by the U.S., Korea, Taiwan, and Japan.

- China: 1,372,700 tonnes

- U.S: 637,304 tonnes

- Taiwan: 287,391 tonnes

- South Korea: 132,305 tonnes

- Japan: 73,578 tonnes

Some of the biggest commercial manufacturers of Nylon fibers are Nylstar, Invista, Asha-Kasei, BASF, Radici Group, and Universal Fibers.

How Much Does Nylon Fabric Cost

There is no standard cost for nylon fabric. It depends on the retailer, country of origin, the quality of the fabric, color, width, and pattern. Most retailers sell the fabric by the yard.

You can purchase it at prices between $3.95-$27.20/yard.

What Certifications are Available for Nylon Fabric

There are no available certifications for nylon. It is a man-made natural product and does not qualify for any of the organic or natural labels that third-party certification organizations use.

What Is the Environmental Impact of Nylon Fabric

We use fossil fuels in the energy-intensive manufacturing of nylon. There are harmful byproducts during the manufacturing process, including nitrous oxide. Nitrous oxide (N₂O) is a greenhouse gas more than 300 times more potent than carbon dioxide.

Washing nylon releases plastic microfibers into the water systems. Some studies estimate that washing textiles like nylon releases the equivalent of fifty billion plastic bottles into the ocean.

Nylon is also not biodegradable, so it remains in the environment indefinitely. Nyon in the ocean and landfills will remain there for hundreds of years.

Nylon is the worst offender among synthetic materials for its effect on the environment. For this reason, many environmental organizations are advocating for alternatives, and governments have begun regulating nylon usage.